In the world of modern construction, precast staircases are rapidly gaining popularity for their efficiency, quality, and versatility. These staircases not only streamline the construction process but also offer superior durability and aesthetic flexibility. In this blog post, we explore the intricate process of designing and detailing precast stairs, with a special focus on complex geometries like curved staircases. Join us as we dive into an insightful conversation with Kalpana, a seasoned expert from StruEngineers, who shares her invaluable experience and knowledge on this critical aspect of precast engineering.

Prashant: Welcome, friends, to another discussion in our series on precast elements. I’m Prashant Gudsoorkar from StruEngineers, and today, we’re going to talk about precast stairs. Staircases are an essential part of any construction site as they connect different levels, facilitating the movement of people and materials.

Today, we have with us Kalpana Ma’am, who has been with us since the inception of our company. She has vast experience in designing and detailing all kinds of precast elements, with a significant focus on staircases over the years. Welcome, Kalpana Ma’am. It’s great to have you here.

Kalpana: Good morning, Prashant. It’s nice to be here.

Prashant: As I mentioned, staircases are crucial for any construction site, and recently, we’ve seen an increase in inquiries about precast stairs. Why do you think precast stairs are gaining so much importance these days?

Kalpana: Well, I’ve been in the construction industry for the past 30 years, and I’ve observed the shift from traditional staircases to precast ones. There are several factors at play. First, precast staircases take very little time to install—just a few hours, in fact. Quality control is also easier because they’re manufactured in a factory setting. Plus, precast stairs are made of high-strength concrete, making them more durable than in-situ concrete stairs.

Prashant: That makes sense. Most of the inquiries we receive for precast stairs are for fire escapes, which, while not particularly aesthetic, are essential. The level of workmanship and the smooth finish I’ve seen even in fire escape stairs is impressive.

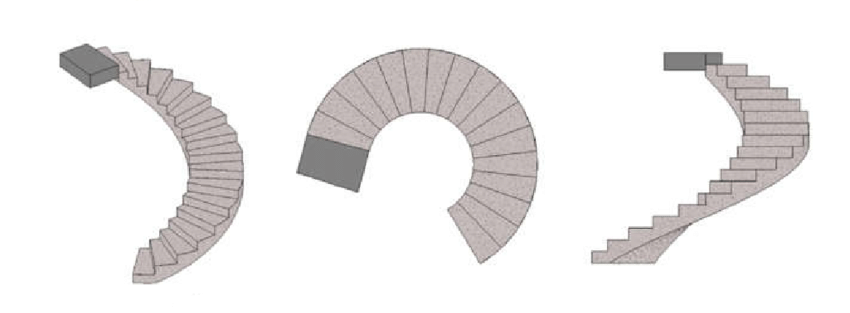

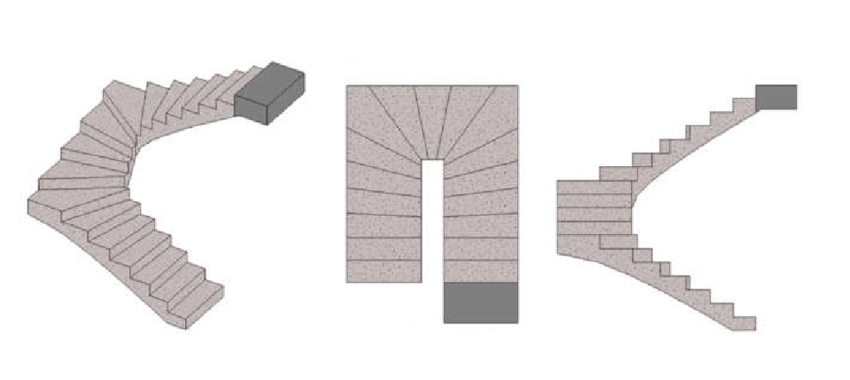

Kalpana: Absolutely. But beyond fire escapes, there are many stairs with more complex geometries, like curved or spiral designs. These are definitely possible with precast, not just straight stairs.

Curved Precast Stairs

Winder Precast Stairs

Image Source: www.researchgate.net

Prashant: So, we can create any type of stair, even those with complex geometries, using precast methods?

Kalpana: Yes, exactly. The main advantage of precast stairs is the smooth finish, which is often difficult to achieve with in-situ construction. For curved stairs, customized molds are made according to the required size, shape, and configuration. These molds are ideal for situations where space is limited, such as fire escapes.

Prashant: But why do we need these complex geometries? Wouldn’t a simple stair suffice in most cases?

Kalpana: Sometimes, the architect requires a more aesthetically pleasing design, which is why curved stairs are often preferred, especially in high-end commercial buildings, luxury residences, and public spaces. In such cases, structural engineers and detailers must work together to create a complex design that meets these aesthetic requirements.

Prashant: I see. Precast stairs, particularly those with complex geometries, are single elements. This makes the design process quite complicated. Isn’t that a headache?

Kalpana: Traditional straight staircases are easier to design and construct, whether in-situ or precast. However, curved stairs present unique challenges, especially with in-situ construction where the mold must be flexible enough to maintain the curve. In a factory setting, the molds are customized, allowing for a smoother finish. The detailing process involves collaboration between architects, structural engineers, and detailers to create precise shop drawings. These drawings must be error-free because any mistake, even by a few millimeters, can result in the stair not fitting on-site, leading to wasted material, labor, and transportation costs.

Prashant: That sounds challenging. But the software we use shows everything in 3D, so it must be easier to ensure that the dimensions are correct before sending the shop drawing to the factory.

Kalpana: Yes, the software helps a lot. The shop drawings must be precise, especially for curved stairs. The dimensions must be exact, and transportation of these elements must be carefully planned. If everything is done correctly, the precast stairs will fit perfectly on-site, but any error can be costly.

Prashant: We’ve talked about the speed and quality of precast stairs. How safe are they?

Kalpana: Precast stairs can be made with slip-resistant surfaces, and slip-resistant strips can be inbuilt in the steps. Robust handrails are also part of the design, which helps prevent accidents.

Prashant: Safety is crucial, especially in construction. Since precast construction involves joining many elements together, connections become vital. How are the connections for precast stairs handled?

Kalpana: Yes, connections are a major aspect of precast construction. We must consider the supporting structure, the anchorage, and how the stair will be supported. The detailing must include precise notes on the shop drawings to ensure that the stairs fit perfectly with the principal structure.

Prashant: That’s a topic in itself. Connections form a crucial part of the design, especially with complex geometries and different structures. How do you handle the loads and forces on curved staircases?

Kalpana: The loading on a curved staircase is similar to that of other structural elements, but additional forces like torsion must be considered due to the curvature. Various loads, including dead load, live load, point load, and seismic load, must be taken into account when designing these stairs. The forces acting on a curved staircase make the design more challenging.

Prashant: Once the design is ready and the shop drawings are sent to the factory, the elements are manufactured. But the real challenge comes when these elements need to be joined together on-site. What types of connections are used, and how do you decide which to use?

Kalpana: Connections are crucial, and they are designed based on the loads and forces acting on the elements. Various types of connections are used, such as steel brackets, welding connections, angle supports, and anchor bolts. The choice of connection depends on the structural design, site conditions, and the specific requirements of the project.

Watch precast connections designs here

Prashant: So, each element is designed to fit perfectly with other elements, and the connections must be pre-planned with precision. Even a slight error can cause issues on-site.

Kalpana: Exactly. These conditions are decided at the beginning of the project with input from architects, structural engineers, and MEP (Mechanical, Electrical, and Plumbing) teams. The shop drawings must include detailed notes on where to place holes, brackets, or corbels to support the stair elements.

Prashant: This has been a thorough discussion on precast stairs, especially those with complex geometries like curved staircases. Thank you, Kalpana Ma’am, for sharing your insights. It was a pleasure having you on this podcast.

Kalpana: Thank you, Prashant, for the opportunity to discuss stair elements. It was my pleasure.

Prashant: The intention of these podcasts is to convey technical knowledge, not just cover the basics of precast engineering. So, thank you again, Kalpana Ma’am, and thank you to our listeners. We’ll be back soon with another podcast discussing more precast elements and structures. Thank you very much.