Precast Concrete Detailing

We are one of the leading providers of comprehensive structural design and detailing services for the precast concrete industry. We specialize in a wide range of precast elements and structures, ensuring unsurpassed precision and cutting-edge innovation. Our global footprint spans India and diverse markets like the USA, UK, Ireland, Sweden, Norway, Canada, UAE, Oman, Qatar, Nigeria, and New Zealand, serving precast manufacturers and builders with exceptional solutions.

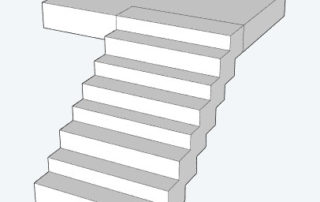

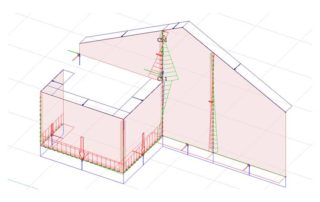

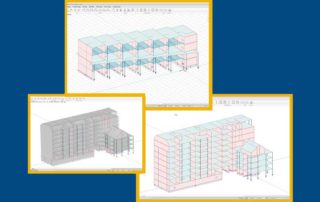

Our meticulous precast concrete detailing expertise breathes life into each element, be it slabs, walls, beams, columns, prestressed hollowcore slabs, slanted double-tee slabs, stairways, including spiral stairways, or curved architectural precast elements. We bring your vision to life with flawless reinforcement layouts, innovative connection designs, and detailed shop drawings. With a strong portfolio of successful international projects across a broad range of markets, StruEngineers is your trusted partner for high-quality, value-driven precast solutions setting the benchmark for quality and reliability in the industry.

We’ll support you at all stages of a precast project

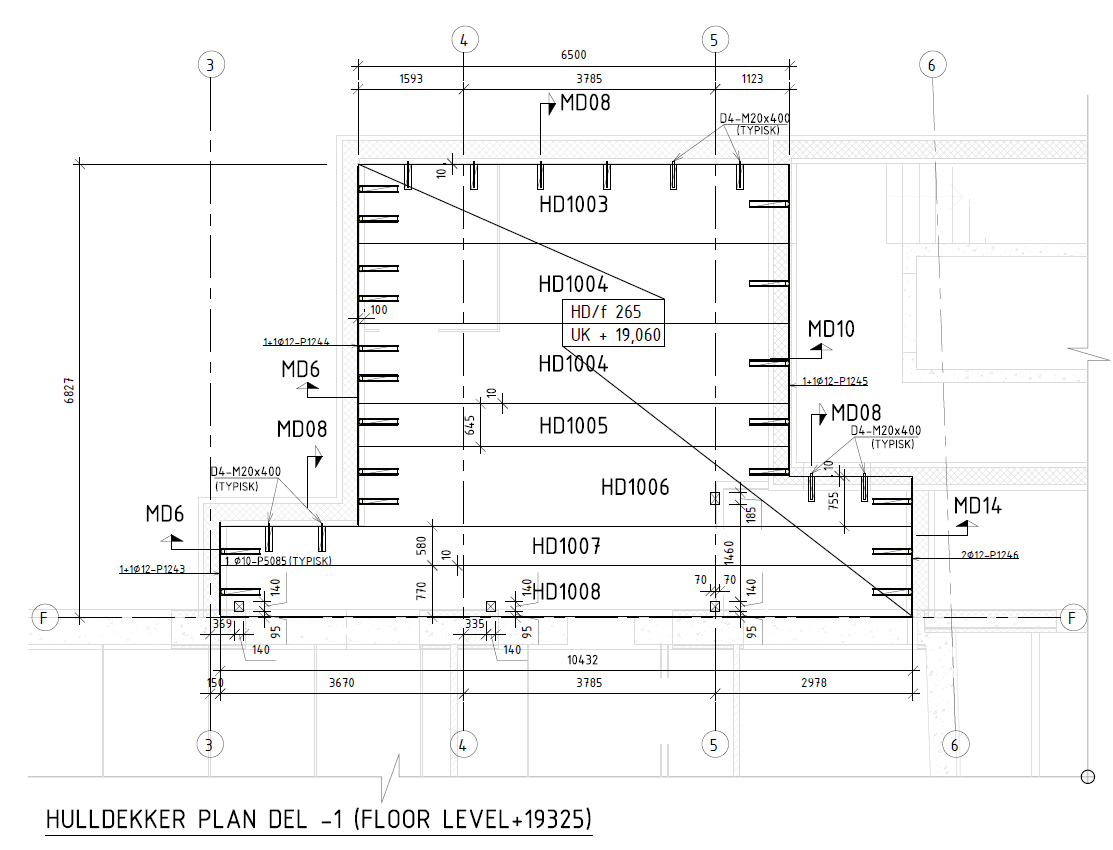

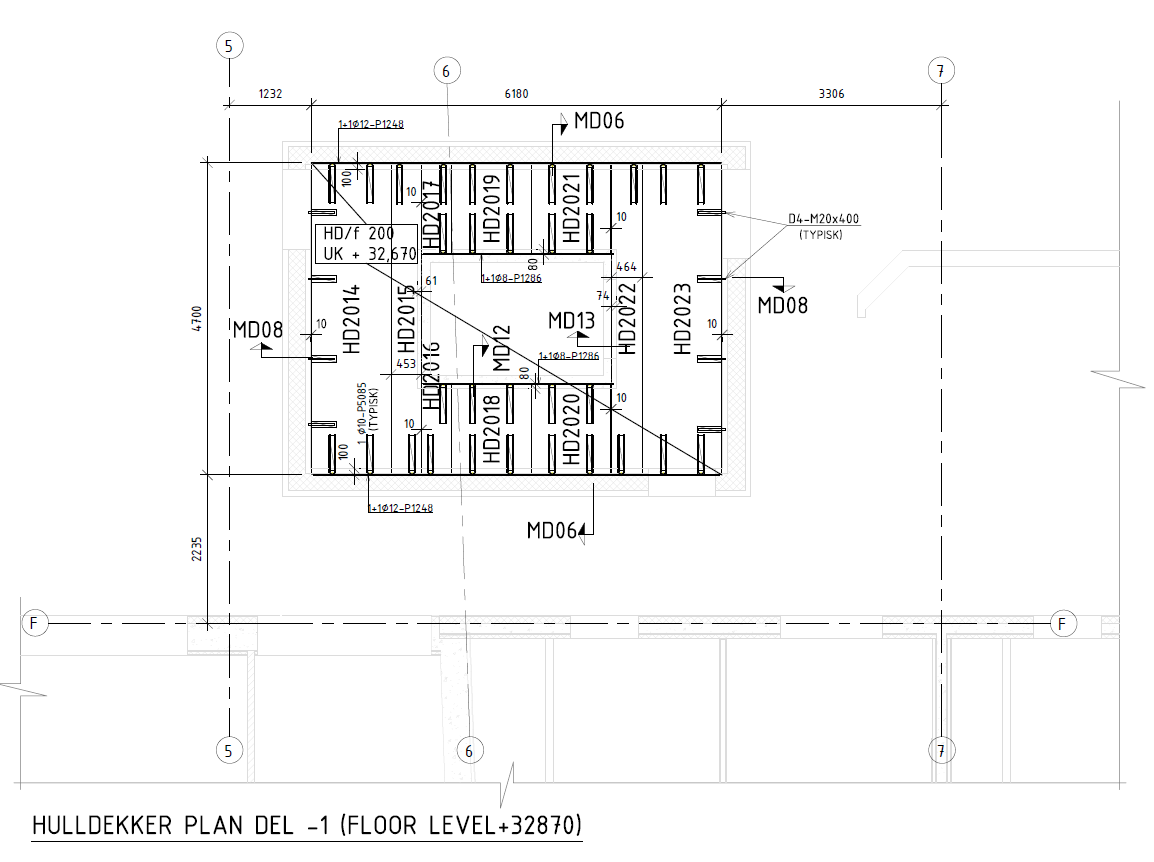

General Arrangement & Erection Drawings

- Preliminary submission drawings for equipment verification, orientation and integration

- Layout Drawings and Framing Plans with several views in one drawing

- Elevation drawings showing all external and internal walls

- Foundation Plan and Anchor Bolt Plan

- Stability calculations for wind load

- Floor Plans, Joint Reinforcement, Reinforcement Plan and Bar Bending Schedules

- Assembly Drawings, Single Part Drawings, Multi Part Drawings, Bolt & Weld Lists

- Ensure heights, overall dimensions, and equipment locations are appropriate

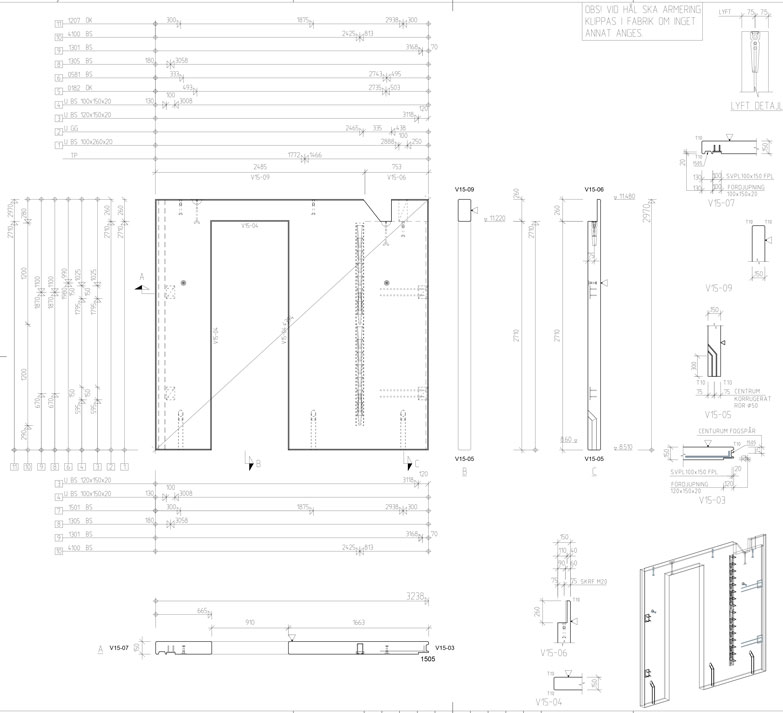

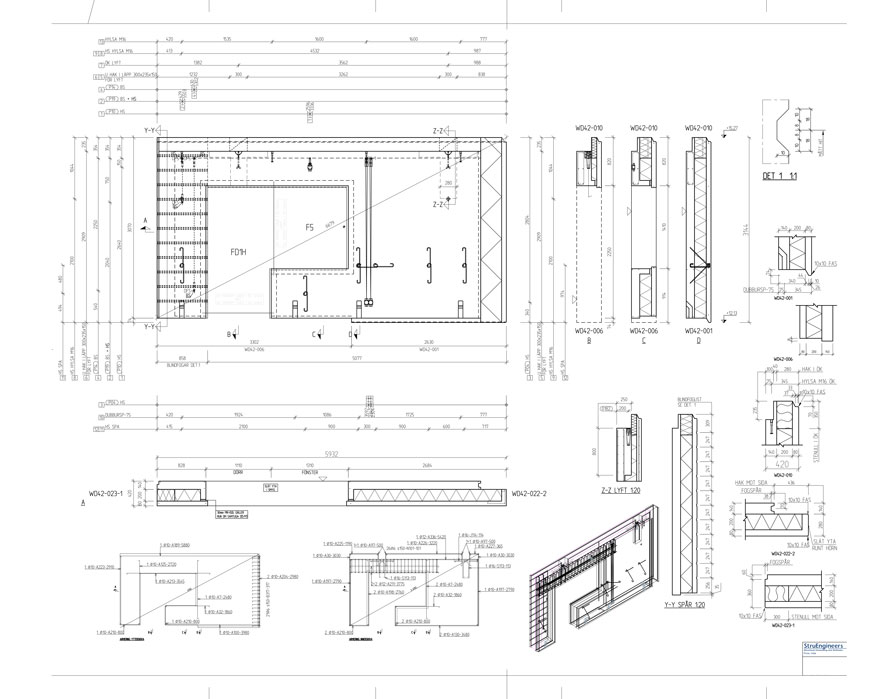

Production & Shop Drawings

- Consistent Precast Elements drawn with the IMPACT BIM system.

- Section Drawings, HVAC Ducting & Equipment Layout, Single Services Drawings

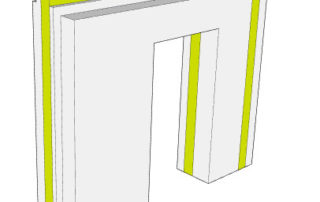

- Elements such as sandwich walls, solid walls,

- Pre-stressed or Normal Reinforced solid slabs and beams

- Balcony slabs, Hollow core slabs, Double T slabs, and Form/Filigree

- Double Twin walls, Inverted T or Ledge beams/girders, stair flights and landing slabs

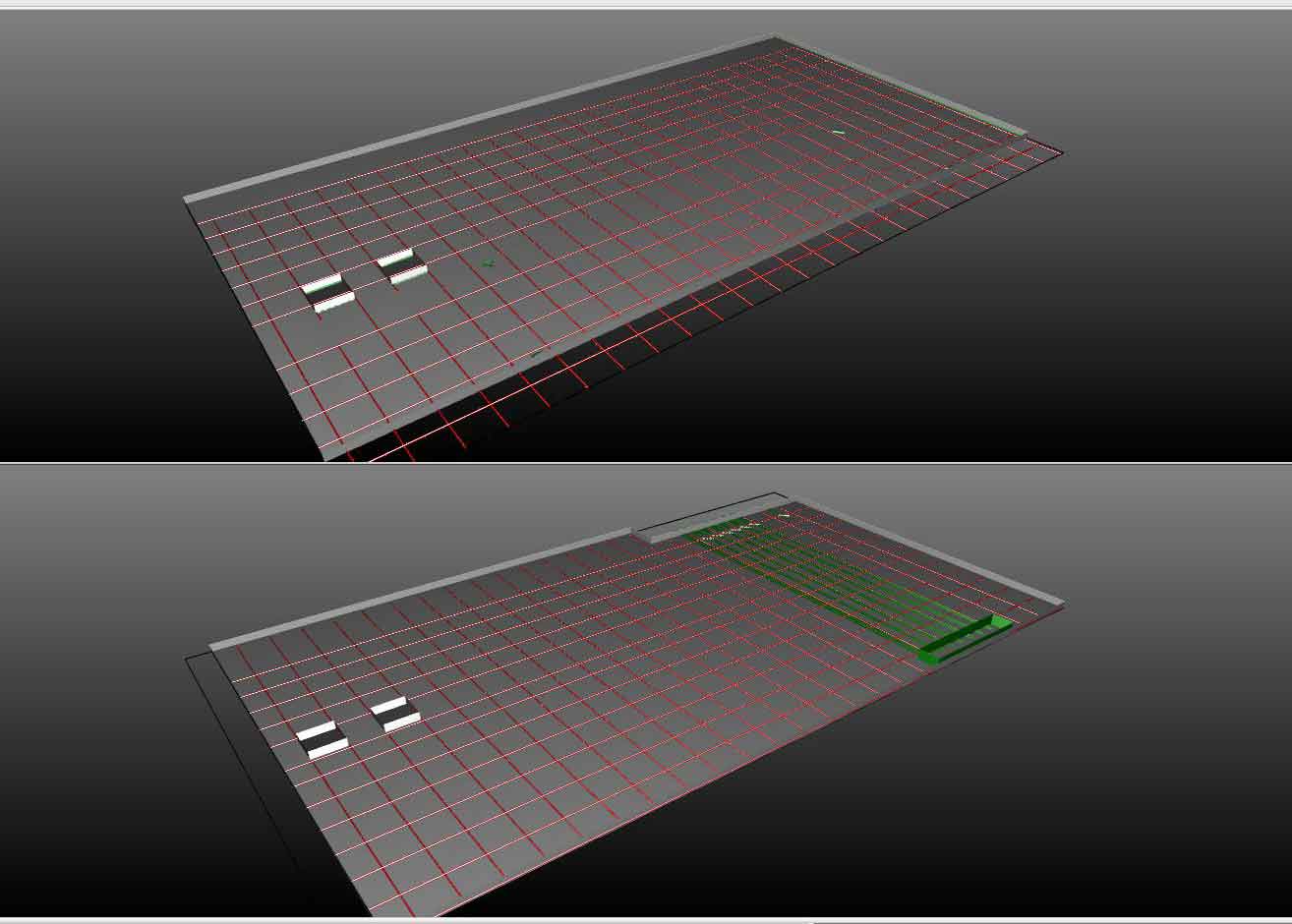

- Modelling & Requisite Data to run the operations with IMPACT BIM system

- Plotters, Lasers, and Shuttering Robots

- Cut and bend reinforcement machinery

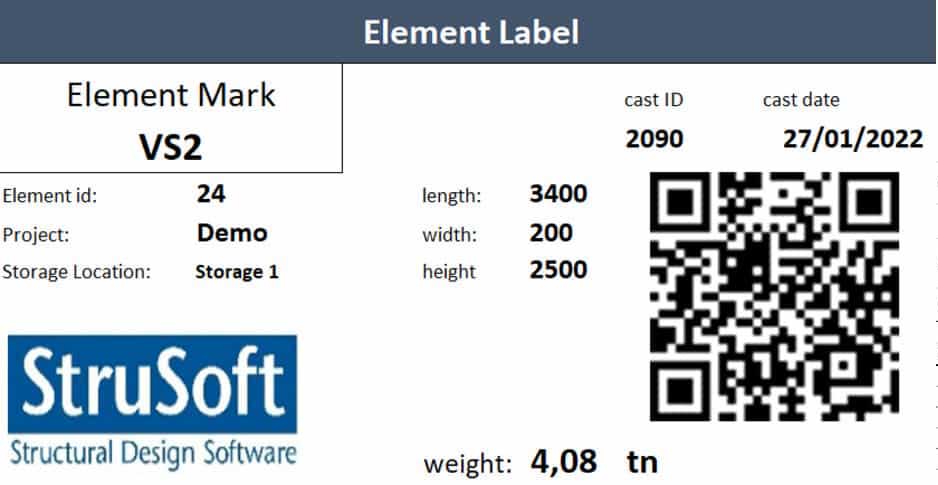

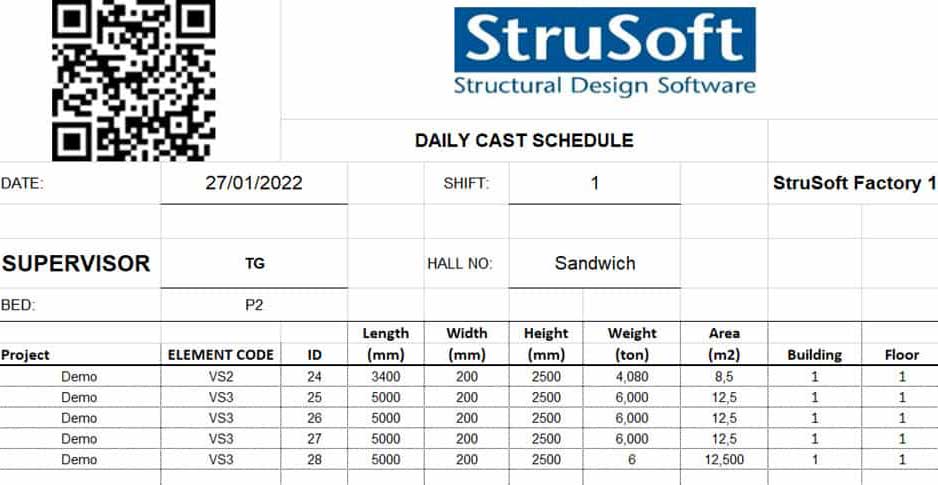

- Production, cast, stack and transport planning

- Any specific machine data format exports e.g., Unitek, BVBS, pXML, HMS, etc.

BOQ, Machine files & Reports

- Modelling & Requisite Data to run the operations with IMPACT BIM system

- Plotters, Lasers, and Shuttering Robots

- Cut and bend reinforcement machinery

- Production, cast, stack and transport planning

- Any specific machine data format exports e.g., Unitek, BVBS, pXML, HMS, etc.

Construction documentation

- Prepare comprehensive and accurate construction documents using IMPACT BIM & BIMcontact.

- List of drawings, mentioning revision log

- List of cast-in materials (embedment)

- List of erection materials (connection plates, etc)

- Full Project Erection Simulation

- Trace elements with IMPACT Project and IMPACT Mobile app

- Visualize and eliminate onsite challenges with BIM Modelling and IFC Model

What to expect when you work with us

What to expect when you work with us

Precast Elements

Precast Concrete Detailing Case Studies: From Concept to Completion

Frequently Asked Questions about Precast Concrete Detailing

Yes, StruEngineers offers customized precast concrete detailing services tailored to meet the specific needs of each project, ensuring that all unique requirements and specifications are accurately addressed in the detailing process.

StruEngineers uses StruSoft’s IMPACT software for precast concrete detailing. This BIM software provides comprehensive tools for designing, detailing, planning, and managing precast concrete elements, ensuring high efficiency and accuracy.

Projects such as commercial buildings, residential complexes, infrastructure developments, and industrial structures benefit from precast concrete detailing due to the need for precision, durability, and faster construction timelines.

StruEngineers’ precast concrete detailing services leverage advanced BIM software to streamline the design and detailing process, reducing errors, saving time, and ensuring accurate production and installation of precast elements.

Precast concrete detailing involves creating detailed drawings and plans for precast concrete elements used in construction. It is crucial because it ensures precision in manufacturing, facilitates efficient construction, and enhances the overall quality and durability of the structure.