In the realm of infrastructure projects, the use of precast elements has gained significant prominence due to their numerous advantages such as improved construction speed, enhanced quality, and cost-effectiveness. However, ensuring the seamless integration of precast elements into these projects requires diligent tracking, quality control, and defect management processes. This article explores the importance of real-time tracking, the role of mobile phones (via app) in capturing details and defects, the significance of photo documentation, and the assigning of responsibilities for rectification, all of which contribute to the successful implementation of infrastructure projects.

Real-time tracking and mobile apps

For efficient and effective project management, the tracking of Precast Concrete Elements should start from the planning stage itself. Real-time tracking of precast elements is an essential facet of project management. It provides a LIVE comprehensive view of the precast supply chain, including the progress of manufacturing, transportation of elements, and their on-site installation.

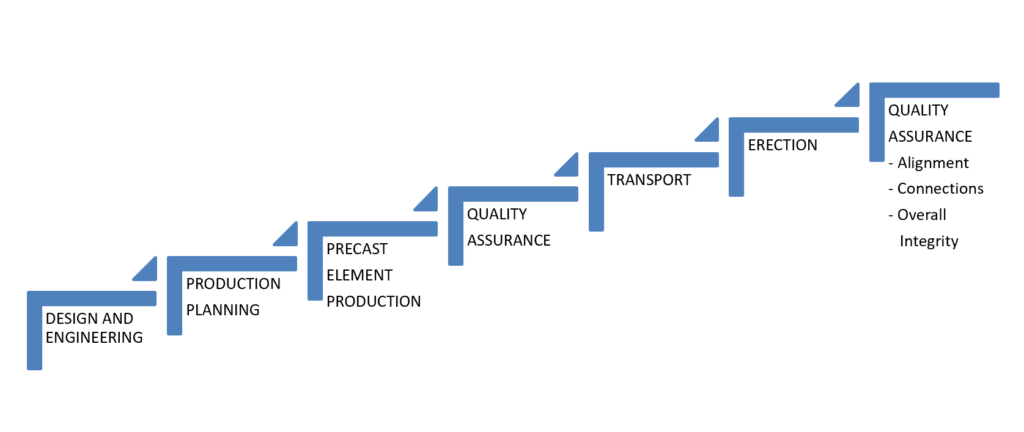

The Journey of a Typical Precast Concrete Element

Complementing this, the use of mobile apps has become increasingly popular for their role in data capture and defect reporting. Most BIM platforms offer purpose-built mobile apps that can scan QR codes attached to each precast element. These codes contain crucial information about the element, such as all its specifications and the location. In the event of any defects, these apps also allow for immediate reporting thereby enhancing the efficiency and accuracy of the quality control process.

How does our Precast BIM platform IMPACT achieve this?

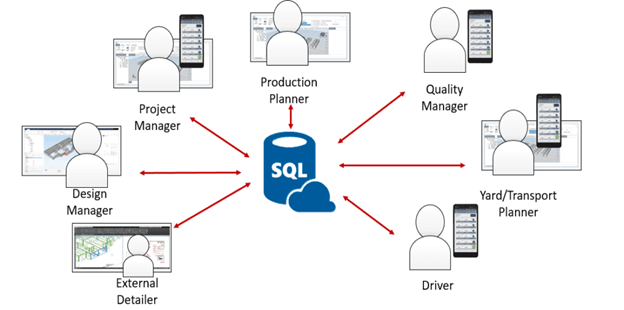

IMPACT is a fully integrated system with an SQL Database at the core which allows you to streamline all your design, production and project processes into one controlled real-time dataset.

Just as important as what IMPACT does, is HOW it does it. With a unique take on an SQL database, IMPACT visualizes everything for you in a 3D model, at all times, and everything is always connected. IMPACT is designed with ease of use in mind, and everyone can learn how to use it efficiently in a few days.

The first step of course, is to define the precast elements in the system.

Defining Precast Elements in IMPACT

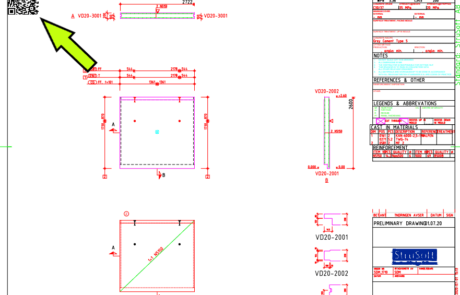

All types of precast elements can be defined in IMPACT (standard as well as bespoke elements). Elements of non-standard shape, size and geometry can be imported with the Linked Element feature. You can import 3D model data from Industry standard software to use for planning in IMPACT, such as integrated detailing IMPACT tools built on top of AutoCAD BricsCAD and Revit. You can also even map your Tekla models directly into IMPACT. AutoCAD, BricsCAD, Revit and Tekla® Structures and if you don’t have any of these inputs, you can still plan with geometry imported Excel and import.

Tracking Precast Elements in IMPACT

IMPACT is a fully integrated system that allows you to streamline all your design, production and project processes into one controlled real-time dataset. Together with the modules and the various software interfaces and IMPACT GO mobile application, IMPACT allows you to keep track of every single precast element at any stage of the design, production or project processes.

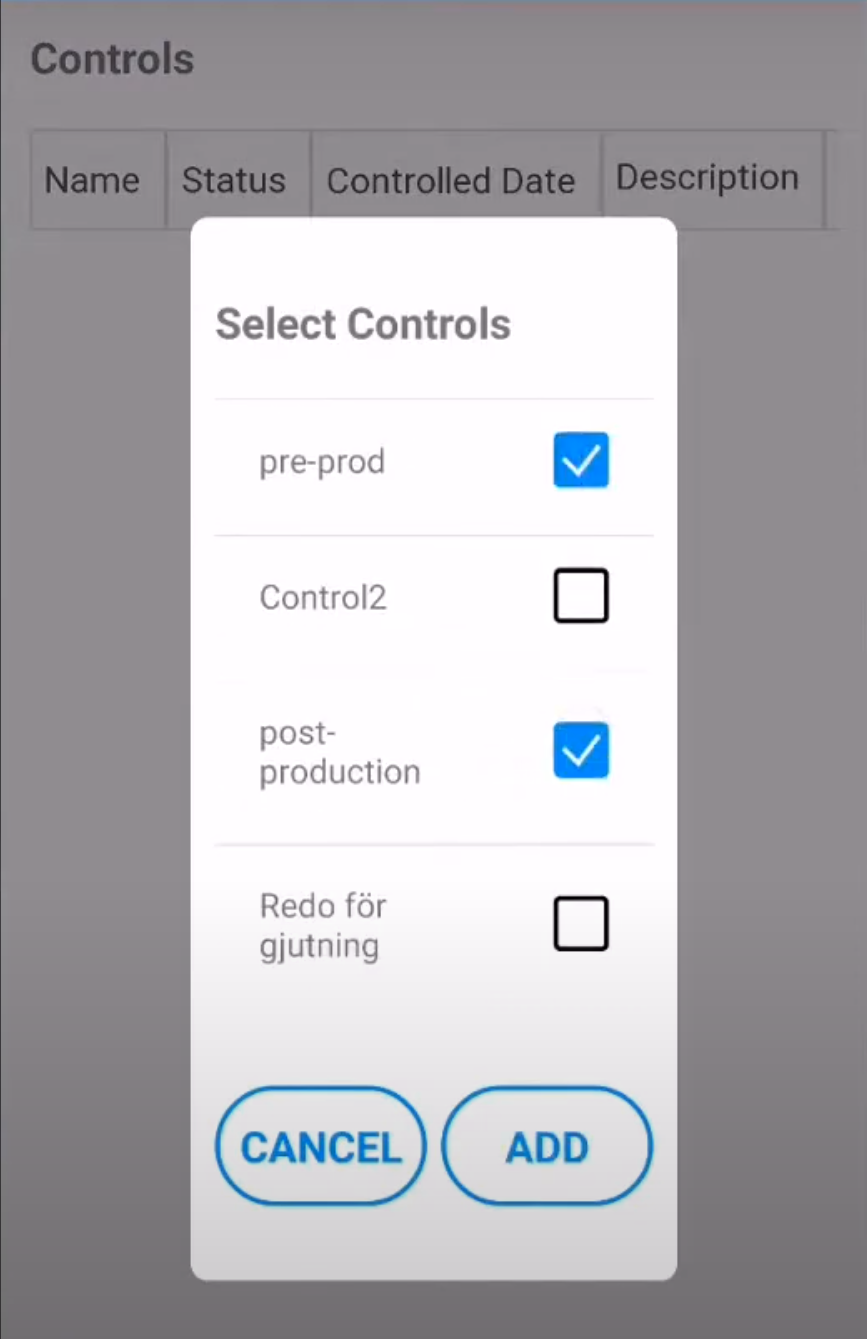

Tracking in IMPACT begins at the Element Controls module. This module is set up to suit your exact workflows and means you have full traceability on every precast element and your procedures.

Element Controls (QA/QC)

Select one of your element tags and click “i” to see all the structural & planning information

Quality checks

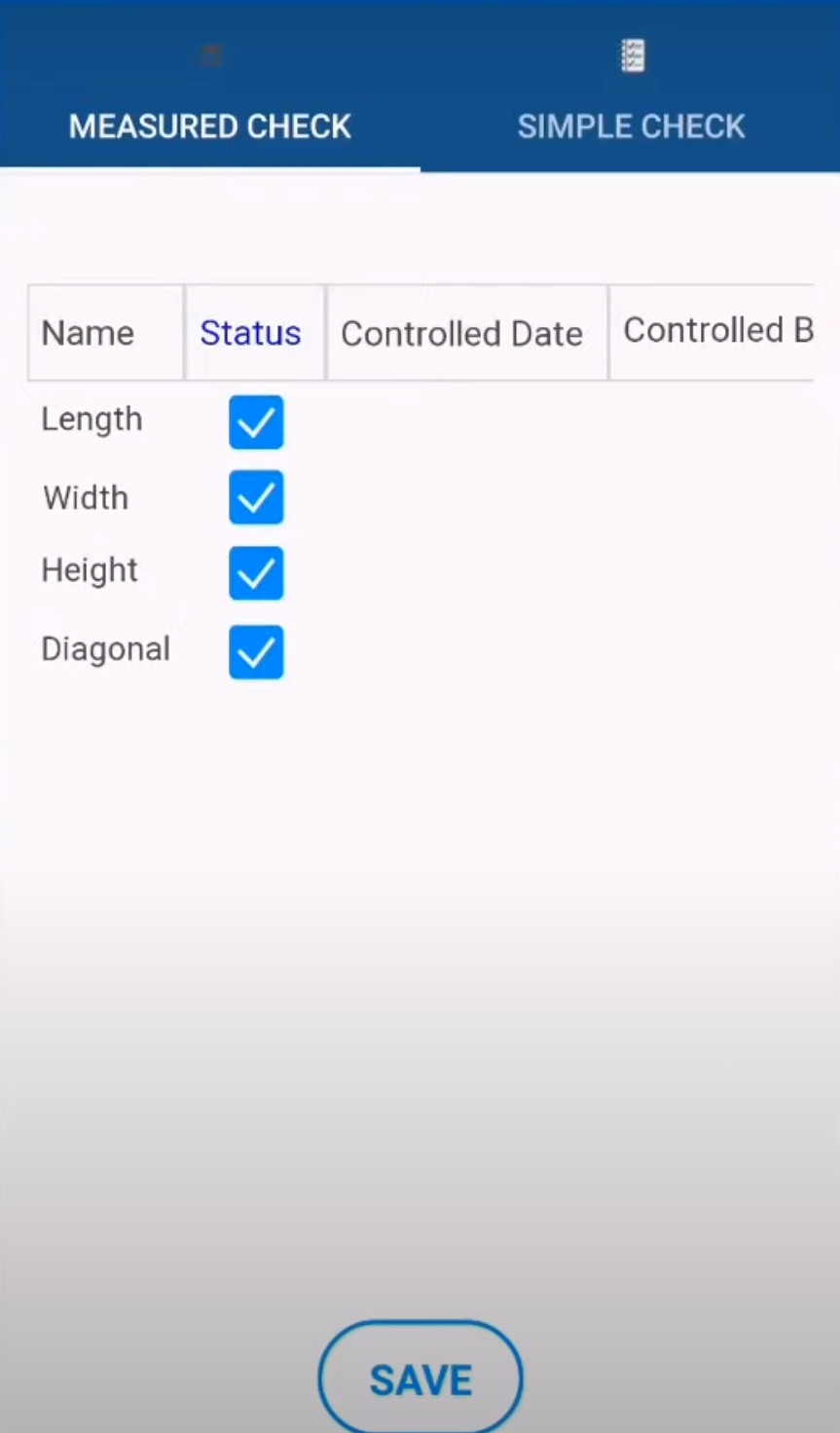

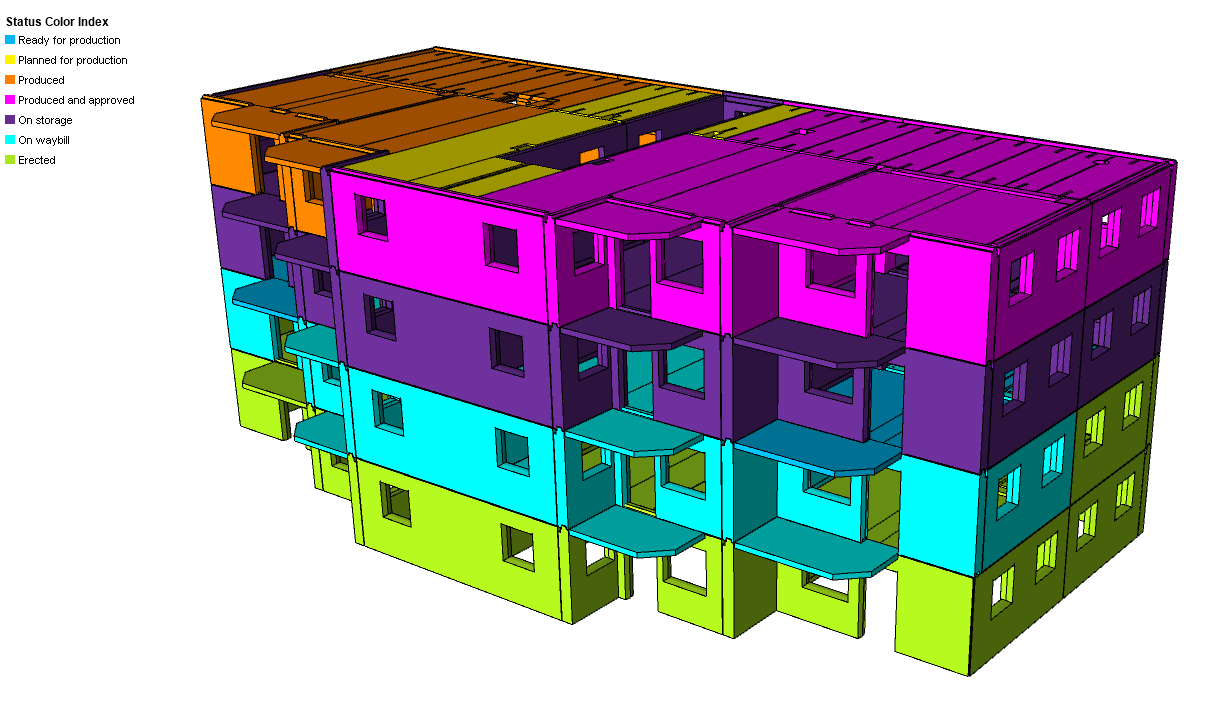

So, depending upon whether your precast element is passed as OK or is registered as having a defect, as you change the status of the element in the Element Control, the colors of the elements in the 3D Project viewer also change, making it easy for all stakeholders to see the exact status of each and every precast element in a project.

Perform quality checks custom made to your process

Defect Detection and BIM Cloud Updates

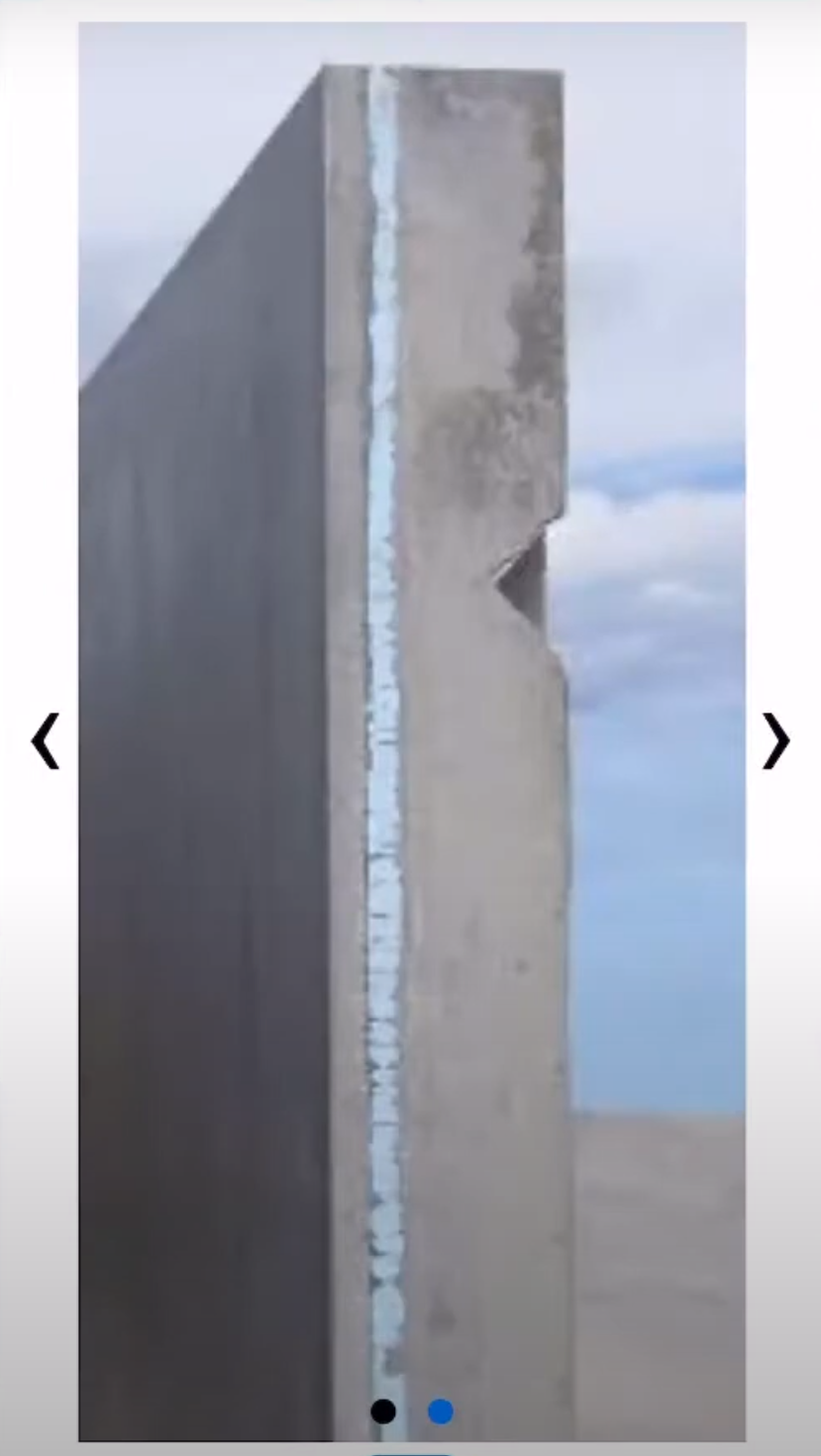

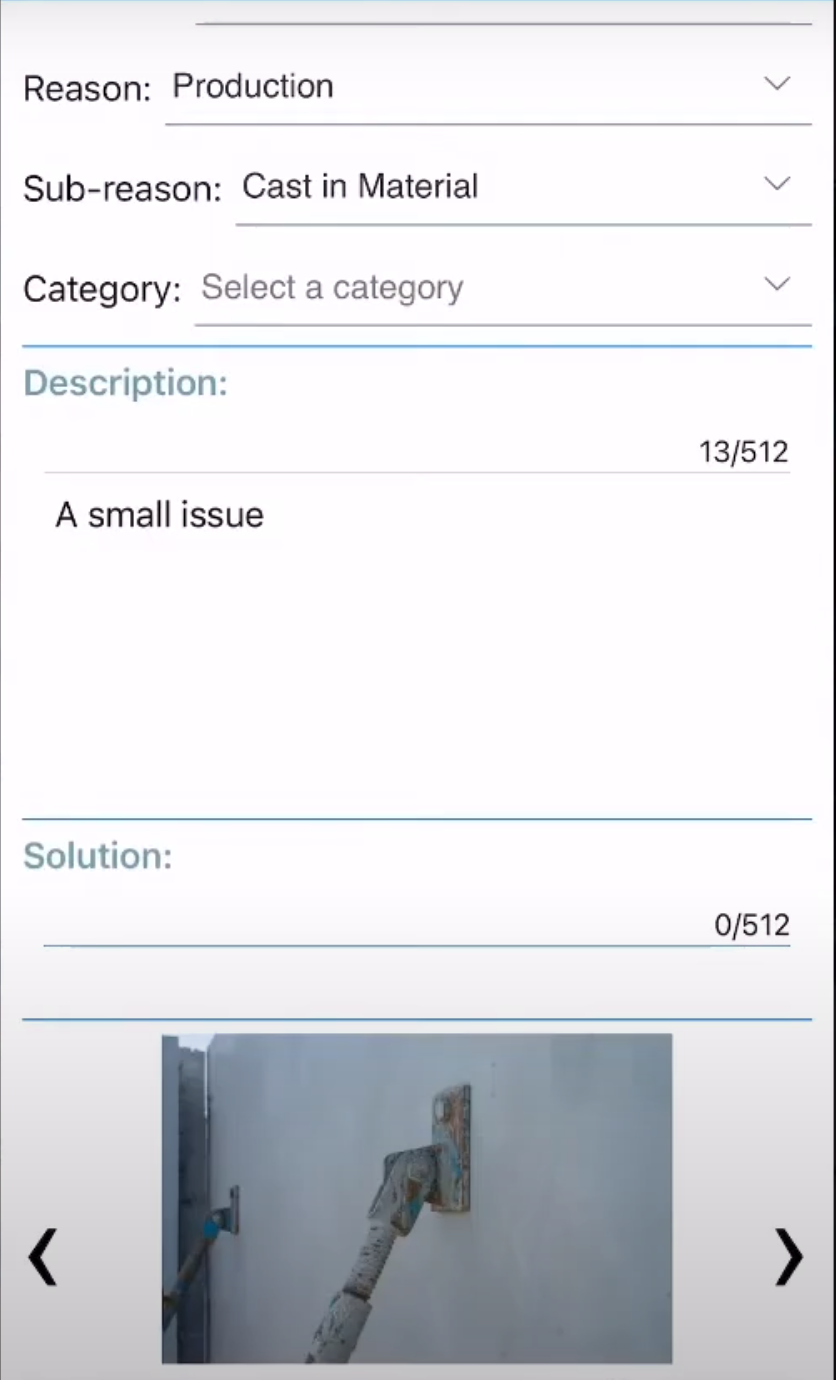

Timely defect detection and management are crucial for the success and longevity of infrastructure projects. Mobile apps help in capturing detailed and multiple images of defects, which can be instantly uploaded to a cloud-based BIM platform. Such real-time defect status updates facilitate prompt responses, reduce delays, and improve collaboration.

The Power of Photo Documentation

Photo-documentation of defects aids in accurate identification and analysis, enables informed decision-making regarding repairs or replacements, and serves as a historical reference for future projects. This transparency promotes accountability and project lifecycle enhancement.

Rectification and Responsibility Assignment

Efficient defect rectification should have a robust system for assigning responsibility. BIM mobile apps often include administrative rights, allowing authorized personnel to assign tasks promptly. This feature facilitates efficient coordination, accountability, and timely rectification of defects, thereby streamlining communication and reducing potential misunderstandings among stakeholders.

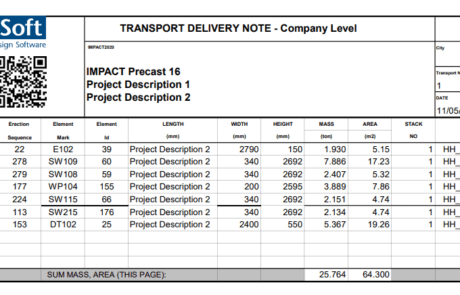

Labels and Reports

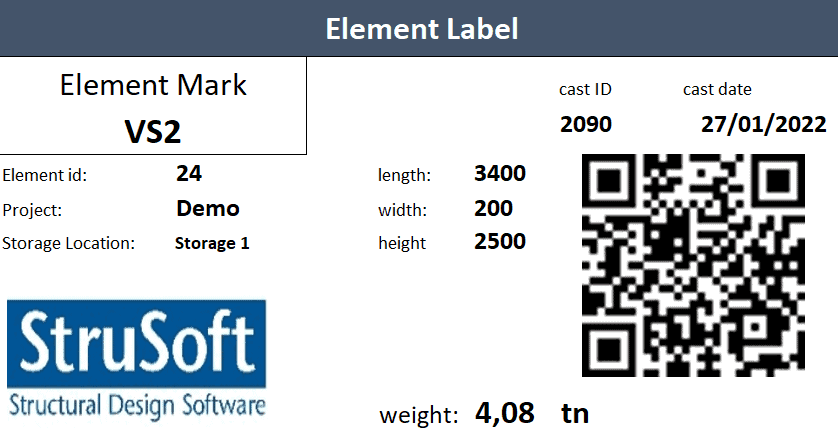

Every precast factory has different procedures for reporting and labelling their precast elements. IMPACT allows you to create and customize labels according to your own specifications.

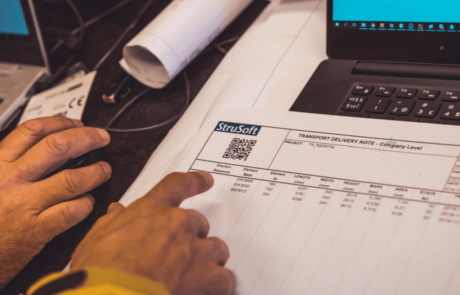

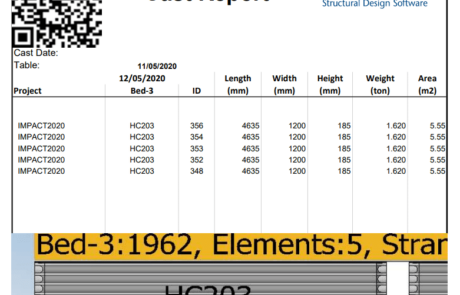

Reports and labels are generated through the Report Tool into Excel spreadsheet templates. These templates can be sent to any printer for physically printing these labels and reports.

IMPACT generates unique QR codes for every element that is designed or imported into the database. Every precast element stored in the database has a unique ID number. Not only does this help you to comply with international certification methods for traceability but more importantly enables you to keep track of every precast element through any stage of the precast design, production or project process in real time.

You can scan QR codes with IMPACT Go mobile app and interact in real time with the central database on Cloud.

You can put QR codes on anything such as Cast Reports, Stack Reports, Transport Delivery Notes and also on Shop Drawings for design approval checks as a part of the IMPACT design module. QR codes can be generated for anything in IMPACT to keep a better track of any area of your precast process.

You can generate QR codes for storage locations in IMPACT and divide your precast stock yard into specific bays. QR codes can be affixed on to the precast elements as shown below:

Combined with the Stack Planning module, you can manage your stock yard and precast element movements by simply scanning the QR codes with the IMPACT Go mobile app and update the storage location with IN and OUT movement of the precast elements.

Advancements with Mobile and Cloud computing mean that you are now able to access your IMPACT precast project data and makes tracking precast concrete elements possible from anywhere and on any device.

IMPACT GO Mobile App

The IMPACT Go Mobile App enables you to connect to and update real time data on your precast elements and projects through an easy-to-use mobile app. Combined with Element Controls and the Status Machine, you can keep track, perform controls and Quality Control checks and update the status of your precast elements as they move through the design, production and the project stage.

A new feature includes enhanced search in the app that allows finding specific casts or transports directly from the database with the click of a button.

IMPACT Status Machine

The IMPACT Status Machine helps you to keep track of your precast elements at any stage in the design, production and project process. It gives you a full 3D model with colors that represent the specific status of every precast element in the project. The status and color changes are continually updated by all stakeholders interacting with the data through IMPACT software tools such as QR codes and the IMPACT Go mobile app.

You can set color status as under (just an example)

Yellow : Planned for production

Blue : Ready for production

Orange : Produced

Violet : Produced & approved

Purple : On storage

Green : Delivered

Through the Status Machine, all stakeholders can get a visual view of the overall status of the precast project. Looking at the 3D model with colors makes it extremely easy for everyone to understand what is going on in the project and keep track in real time, including multiple projects and multiple factories in a table format.

Planning Multiple Factories

The IMPACT Resource Manager helps you plan and manage your precast production and project processes; controlling element storage locations, element disorders, element rejections, element casting across multiple projects; multiple factory locations, and much more.

The data from all your precast factories is combined in table views with many options for sorting and filtering data to handle multiple precast elements, multiple projects in multiple factories.

The Element Swap feature

In most precast projects, a number of identical elements are involved. Though identical in all respects, each precast element is allotted a unique ID in the precast BIM software. It can occasionally occur that an element intended for a specific location in a project is either mistakenly or intentionally directed to another location within the project. To compensate for such a redirection, a new similar element with a distinct ID must be dispatched to the originally intended location.

To avoid potential confusion surrounding such relocation of precast elements, it is imperative for BIM software platforms to incorporate a feature that accounts for such occurrences. This ensures that stakeholders have clear visibility and tracking of the precast elements that are swapped in this manner. At IMPACT BIM, we recognize the importance of this functionality and have integrated this feature into our software, thereby eliminating any confusion or ambiguity.

Conclusion

The role of tracking and quality control in infrastructure projects featuring precast elements cannot be undermined. Real-time tracking, mobile apps, photo documentation, and cloud-based collaboration have revolutionized defect detection and rectification. By effectively leveraging these tools, infrastructure projects can achieve higher quality assurance, streamline defect management, and deliver successful, resilient structures and IMPACT achieves all this efficiently and effectively.

FAQs: Optimizing Infrastructure Projects with Advanced Tracking and Quality Control of Precast Elements

QR codes provide a unique identification for every precast element, enabling stakeholders to track each element’s journey through the precast process in real time. This facilitates compliance with international certification methods for traceability and allows for efficient management of the precast stock yard, enhancing operational efficiency and reducing the risk of errors.

The IMPACT BIM system is a fully integrated platform that allows for the real-time tracking of precast elements throughout the design, production, and project stages. With features like the Element Controls module and the IMPACT GO mobile app, it offers full traceability and quality control, enabling stakeholders to monitor the status of each element and perform quality checks efficiently.

Photo documentation of defects is a powerful tool for accurate identification and analysis, enabling informed decisions about repairs or replacements. It provides a visual record that enhances accountability, aids in the rectification process, and serves as a historical reference for future projects, thereby promoting transparency and project lifecycle improvement.

Mobile apps, often integrated with BIM platforms, facilitate the capture of data and reporting of defects directly from the construction site. By scanning QR codes attached to each precast element, stakeholders can access detailed information, report defects, and ensure immediate action, significantly improving the accuracy and efficiency of quality control processes.

Real-time tracking of precast elements is essential for efficient project management as it provides a comprehensive view of the precast supply chain, including manufacturing progress, transportation, and on-site installation. This visibility ensures timely decision-making, enhances coordination among stakeholders, and improves overall project efficiency.