About our client

Our client has been involved in manufacturing RC frames and modular precast elements since 2010 and has seen rapid growth ever since, working with some of the most high profile clients and high profile projects.

Hybrid precast refers to a construction technique that combines the use of precast concrete elements with other materials such as steel or wood to create a building system that takes advantage of the benefits of both materials.

The use of hybrid precast construction offers several benefits, including reduced construction time, improved quality control, and increased flexibility in design. Additionally, the combination of different materials allows for a wider range of architectural possibilities, enabling designers to create structures that are both aesthetically pleasing and functional.

Naturally, our client adopted the hybrid system as the benefits from offsite manufacturing of precast elements and in-situ concrete are enormous. Prefab concrete elements save time, offer better quality product whereas in-situ offers flexibility with designs and aesthetic approach.

What led to the selection of StruEngineers over other options available?

StruEngineers stood out due to its extensive experience in the European market since its inception and armed with StruSoft’s IMPACT BIM, our precast team has been able to provide excellent services in precast design, detailing, production, and project planning.

The client chose IMPACT BIM for both their onshore and offshore teams, which gave an added advantage of seamless communication on a single platform. We assisted the client in establishing IMPACT standards right from the initial stage and trained their onshore team.

Use of cloud platform:

IMPACT is cloud-enabled, therefore, irrespective of location; IMPACT cloud offers great flexibility with respect to scalability of design resources, flow of information, central database and status updates.

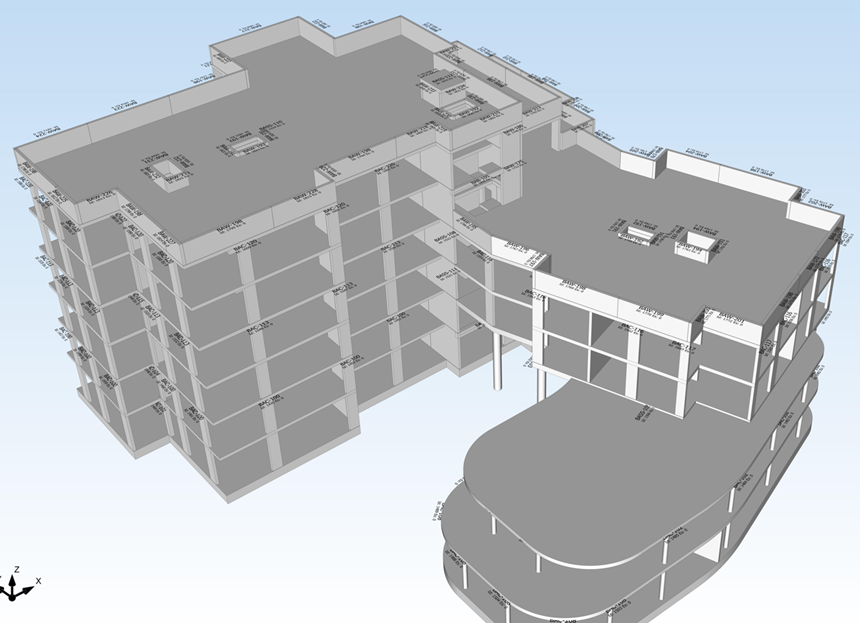

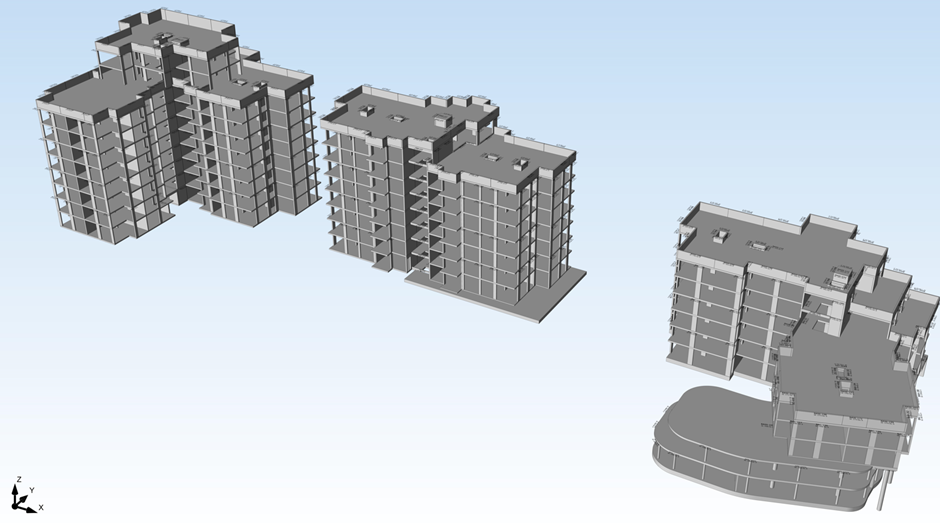

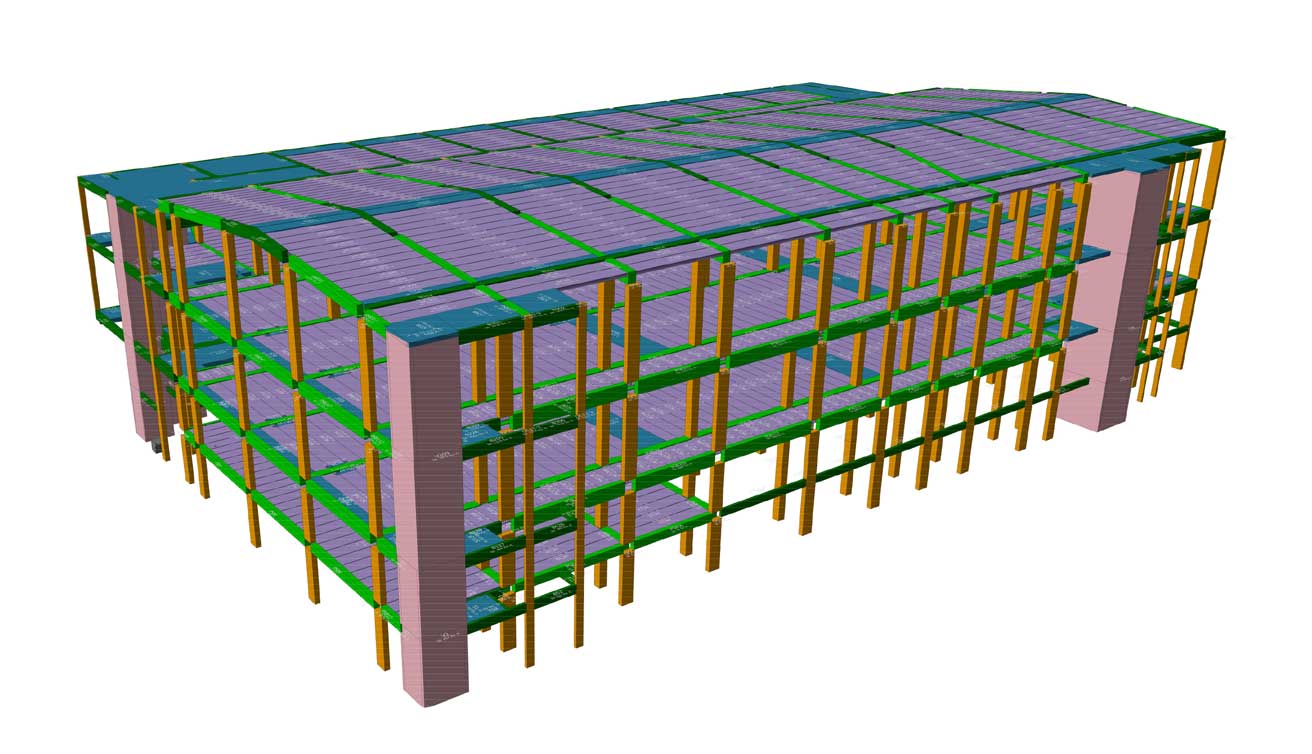

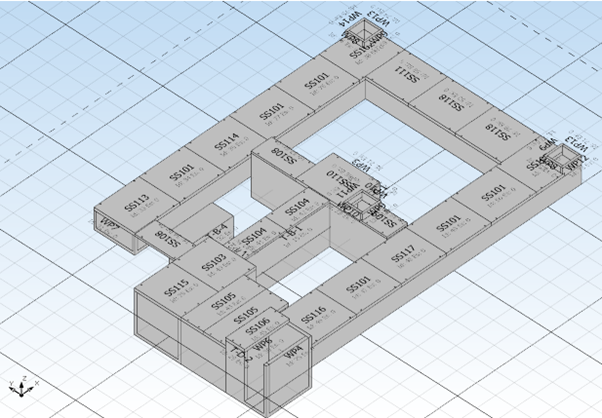

IMPACT 3D models

About the project/s:

This narrative is not about a single project – we have ongoing projects with this client. The team of IMPACT BIM modellers at StruEngineers is responsible for producing the tender/pre-bid model as well as the finalized working BIM model. The pre-bid BIM model provides clarity to all stakeholders involved in the project and enables visualization of the structural load paths. Additionally, it helps with material quantification and planning of site resources, such as crane management, allowing for better planning and execution.

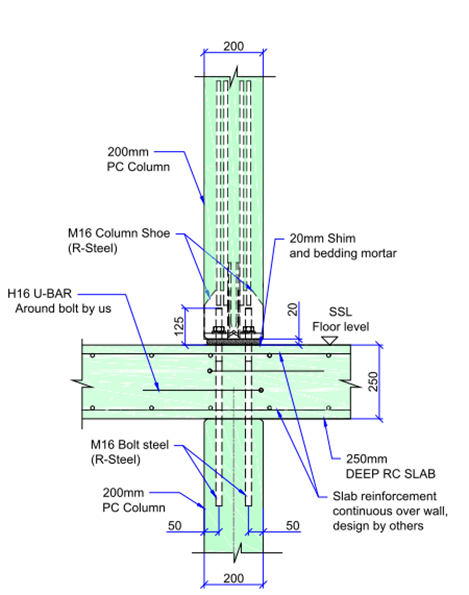

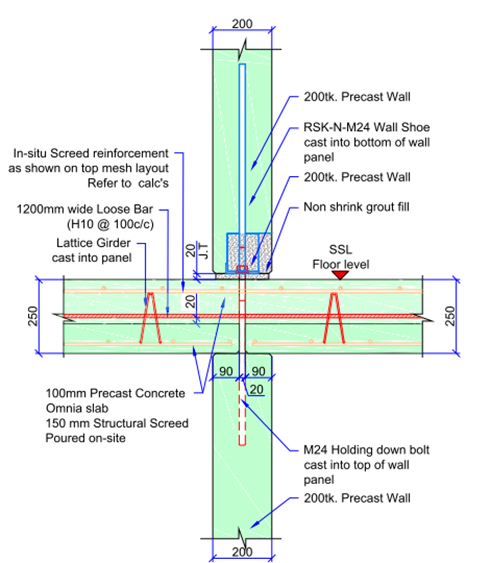

As an offshore team, our responsibility is to create a complete structure model and generate GA drawings using Revit BIM models and CAD drawings provided by the client. Our scope of work may vary from project to project, but the primary focus remains on designing and detailing Precast Columns and Core Precast walls. The other elements are cast on site; that’s why these projects are Hybrid Precast.

Shop Drawings

Challenges and how they are mitigated

One of the primary challenges we face during the execution of this project is managing the flow of information. We frequently receive updates and modifications to the architectural designs and specifications from our client, which can have a significant impact on the structural design. Fortunately, our BIM platform, IMPACT, is equipped to handle these changes seamlessly and implements modifications to the structure at various levels throughout the BIM supply chain.

- As the IMPACT data is in the central cloud database all stakeholders are connected at same time irrespective of their location

- IMPACT offers great visibility of data and projects in 3D format which makes life easier for all stakeholders

- Modifications and variations can easily be adopted in 3D modelling stage and reflection of changes in shop drawings are tracked automatically as everything is connected

- Shop drawing generation is completely automatic, so our team has to put no efforts at all for shop drawing generation of bar bending schedules which are bottlenecks in many projects and potential error happens