Background

This case study focuses on a precast construction project undertaken by StruEngineers in Mumbai, India. The project aimed to provide housing for the Economically Weaker Sections (EWS).

Illuminati, part of the Naman Group, served as the EPC contractor, while StruEngineers was chosen to handle the precast design and detailing.

The Project

Ground + 4 floors

Area : 20,000 sq.ft.

40 low-cost apartments

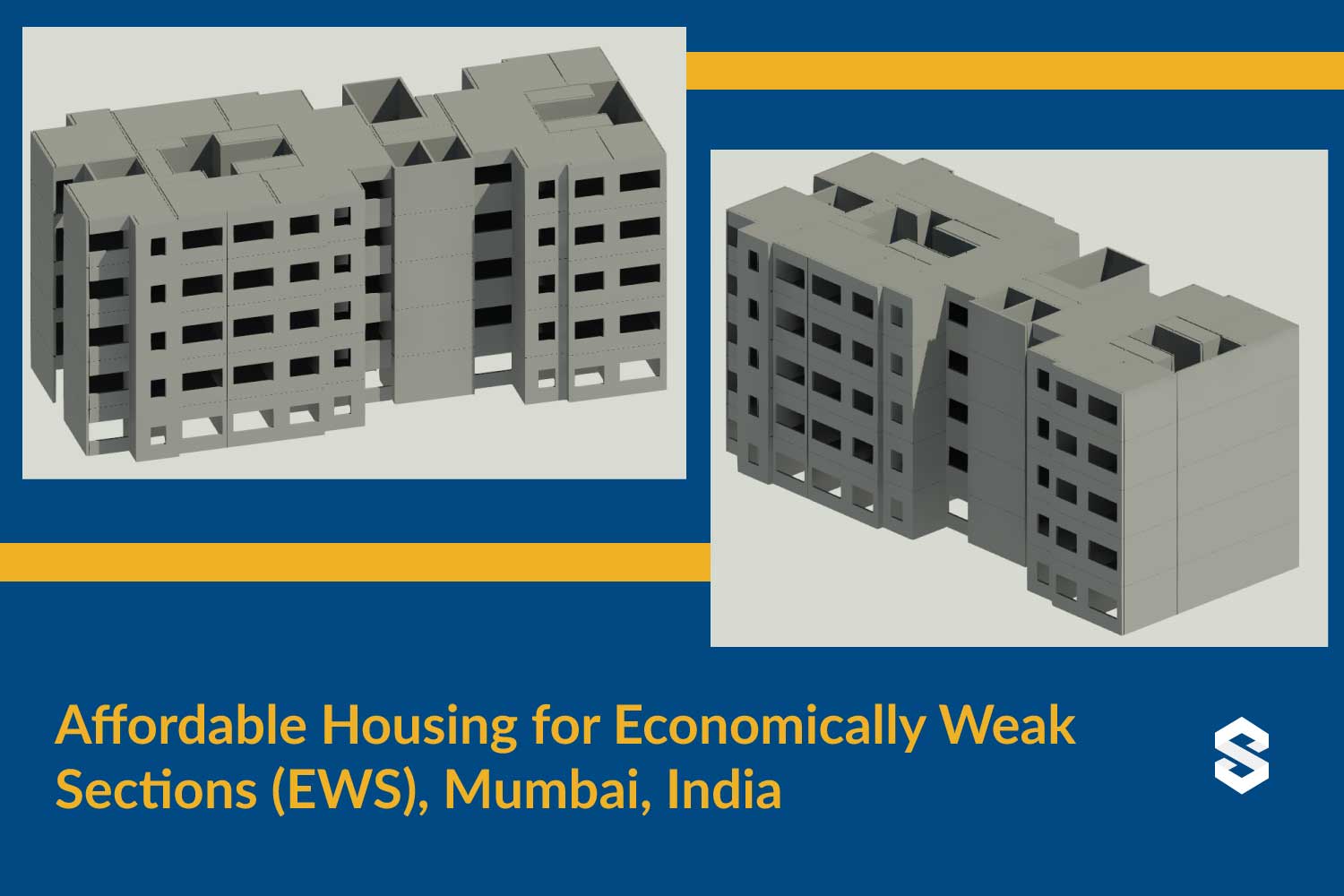

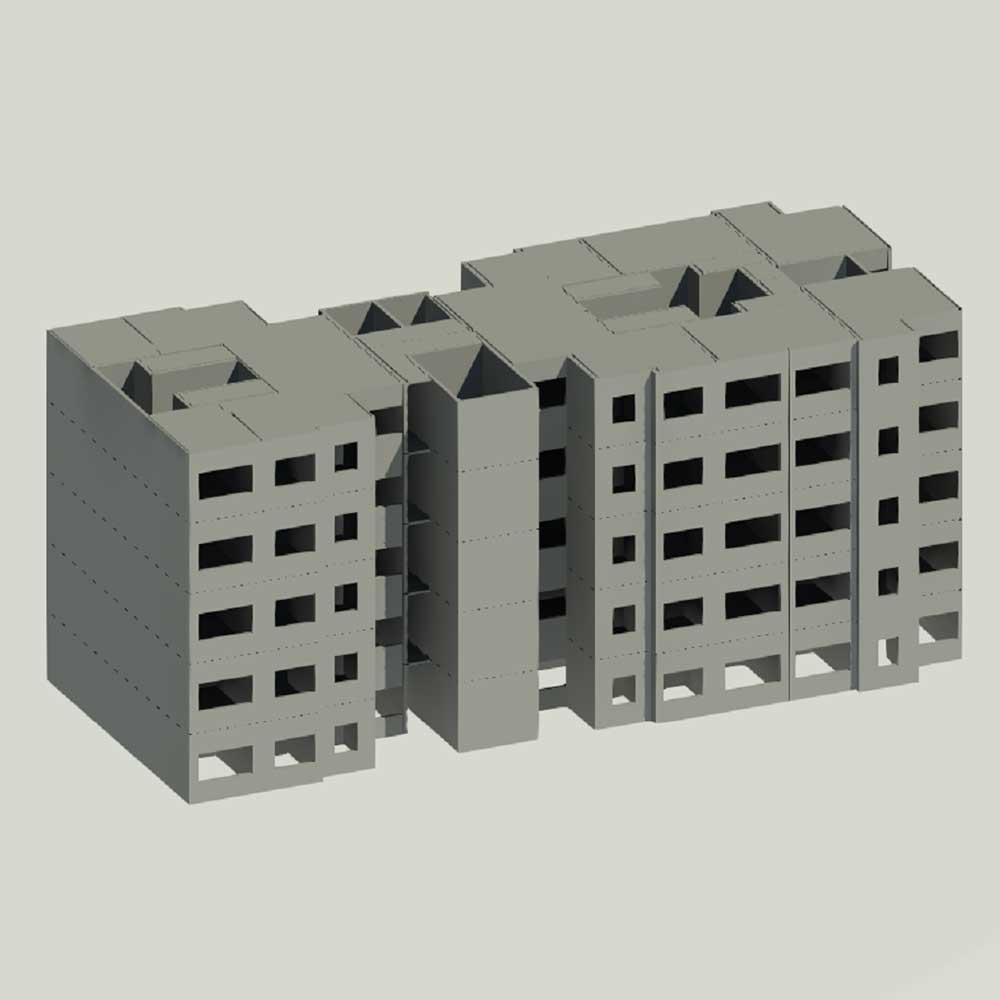

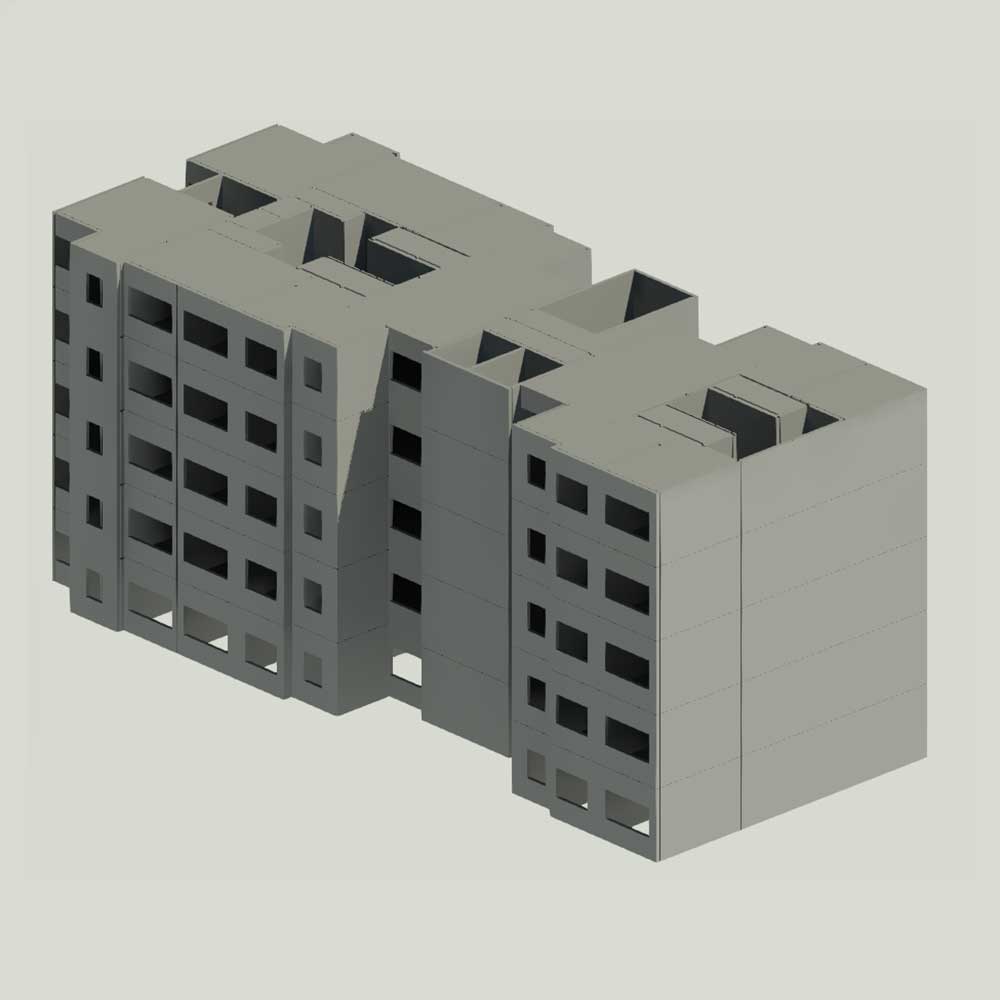

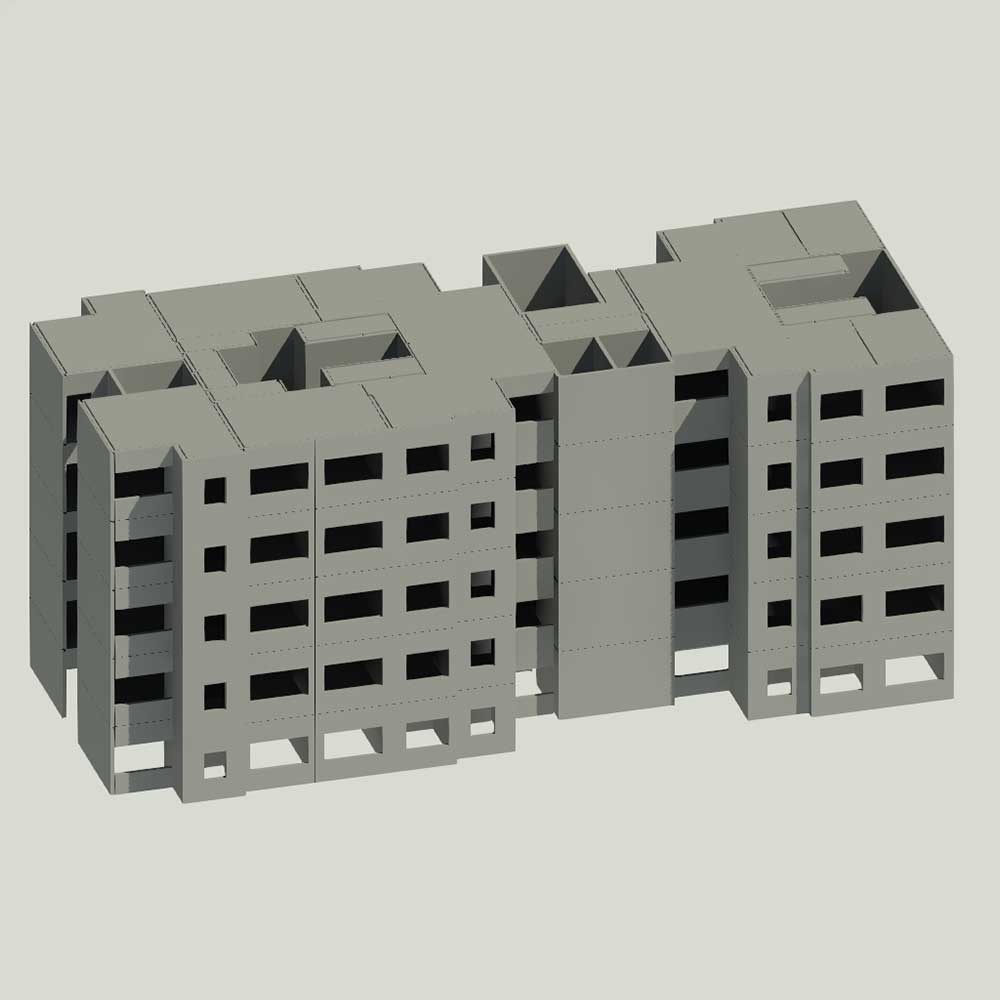

3D models

The Arrangement

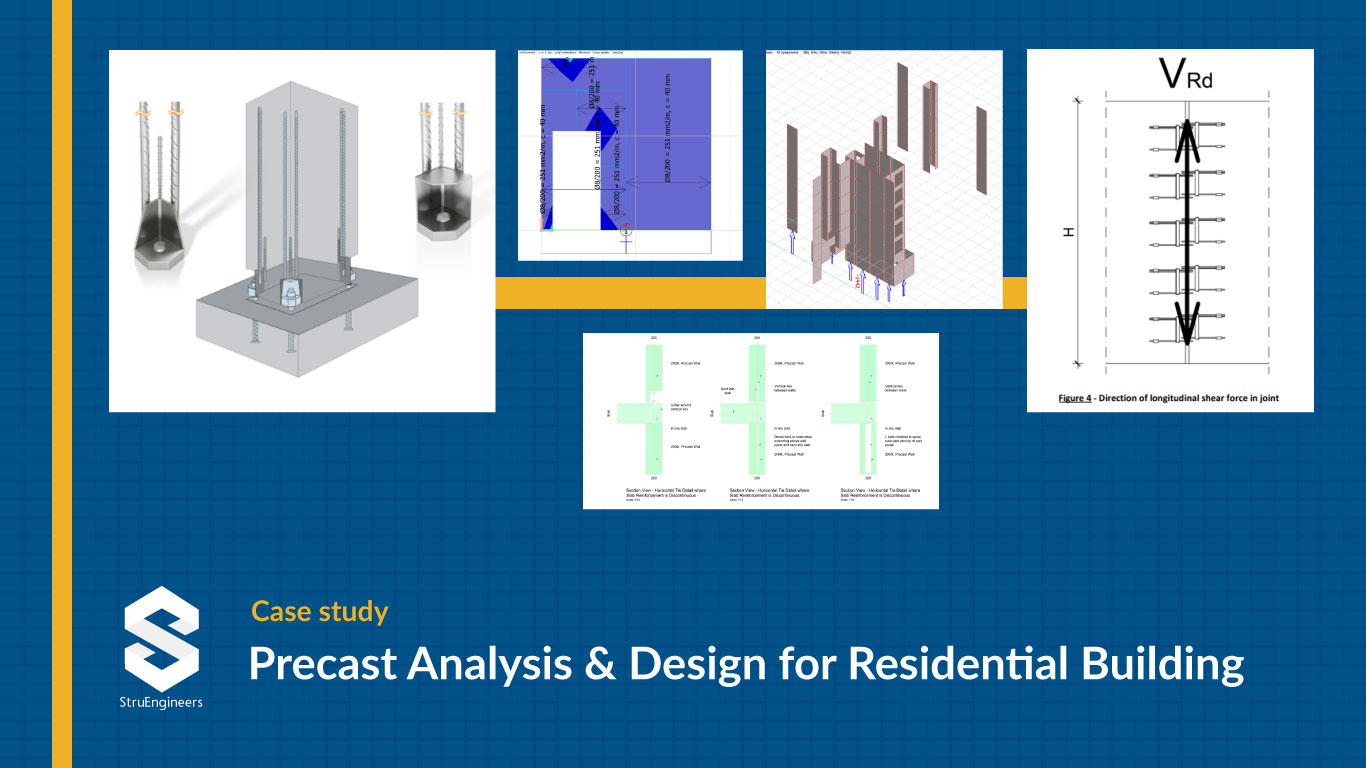

StruEngineers employed their proprietary BIM Platform, IMPACT, which is not only feature-rich but also remarkably user-friendly, to facilitate the design and detailing of precast elements. Additionally, the platform was utilized for the overall structural design, incorporating the seamless integration of MEP systems in a highly efficient manner. To ensure a flawless design, IMPACT conducted clash detection procedures, effectively eliminating any potential design errors. Moreover, the structural stability of the entire building was assessed through real-life stress simulations, considering natural forces and various loads that the structure would encounter during its usage. These comprehensive evaluations were carried out before commencing any activity on site.

One of the key advantages offered by precast technology is its ability to significantly reduce construction time without compromising the quality or performance of the structure. Let us see how this was achieved.

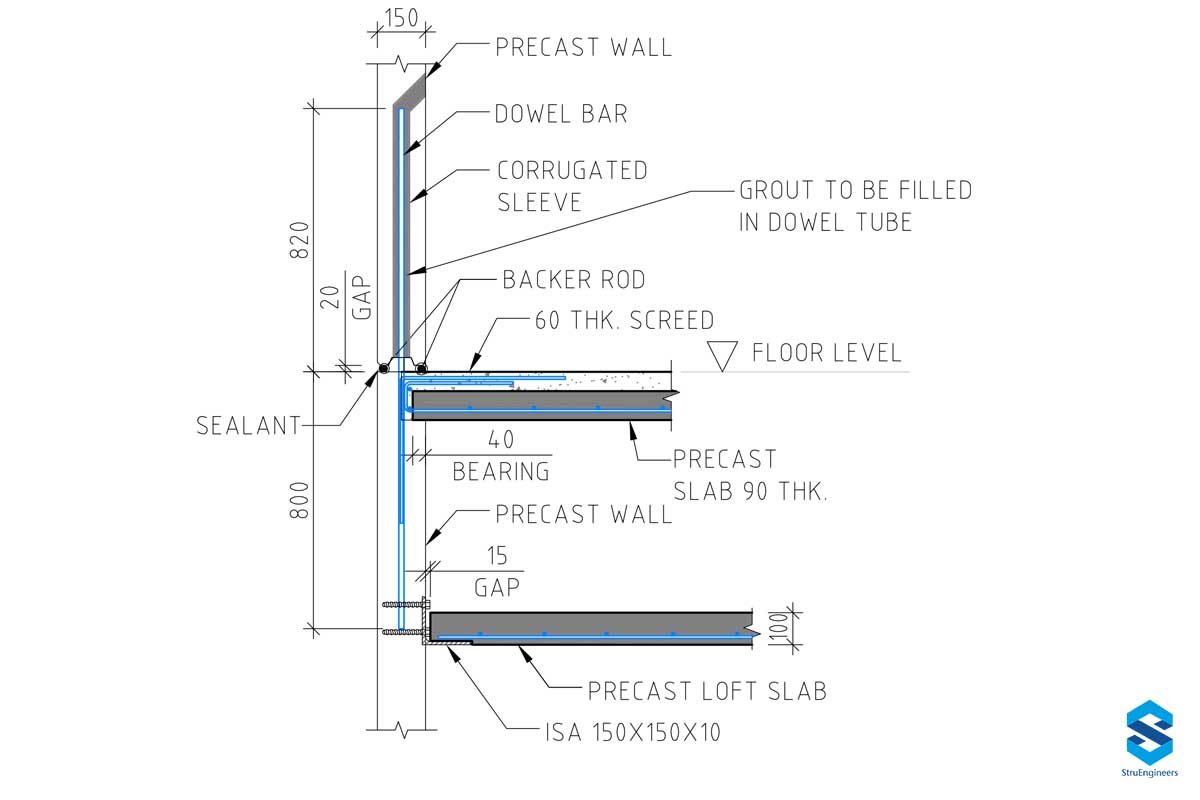

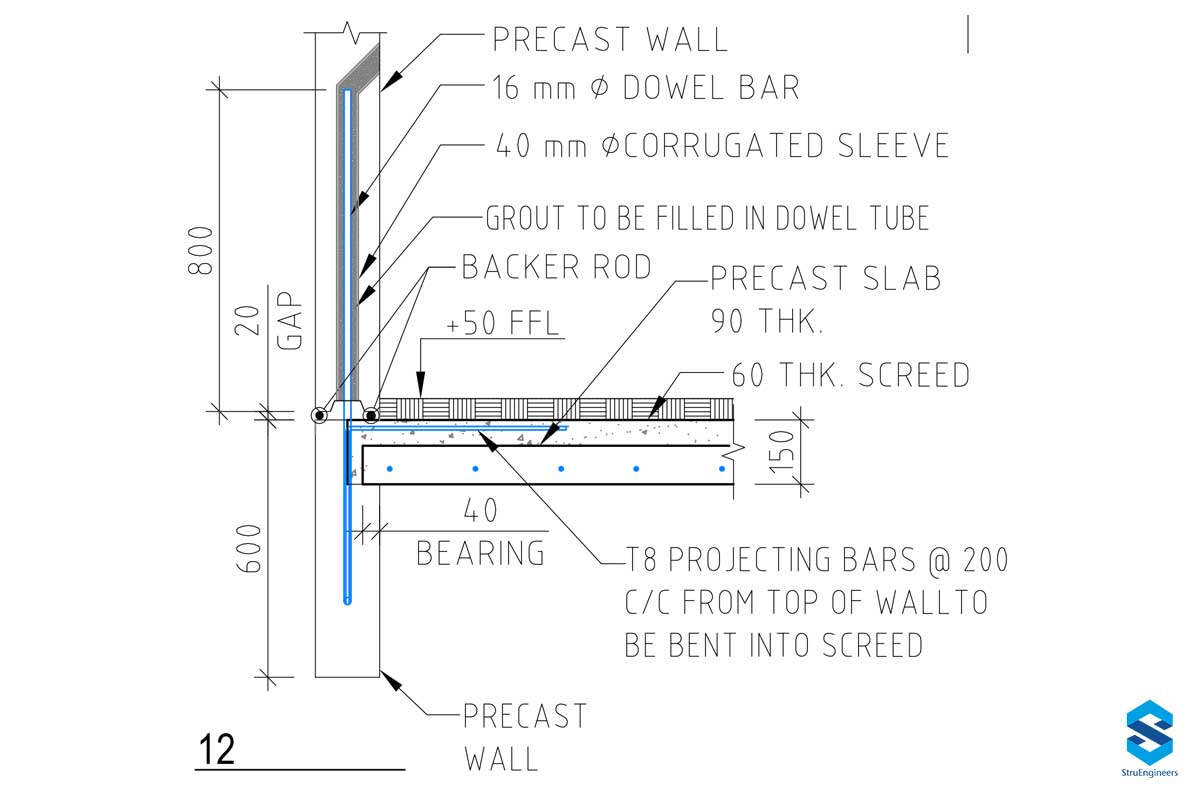

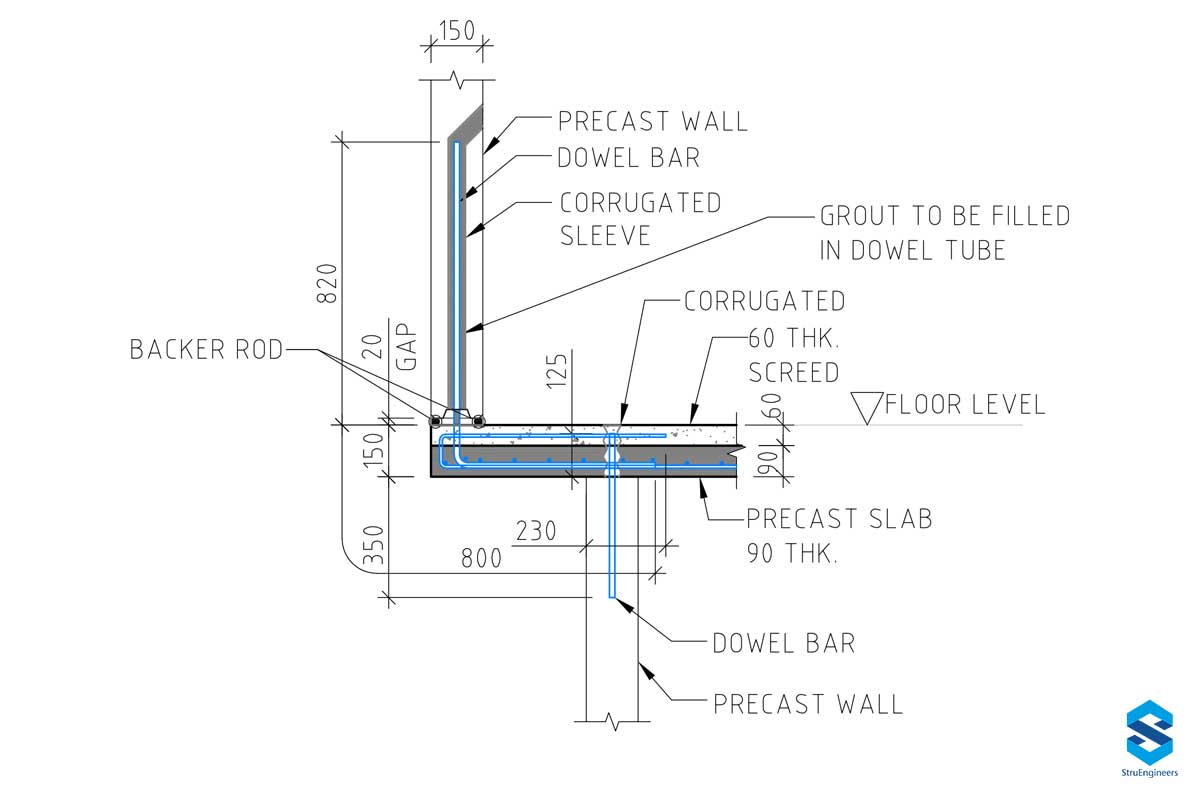

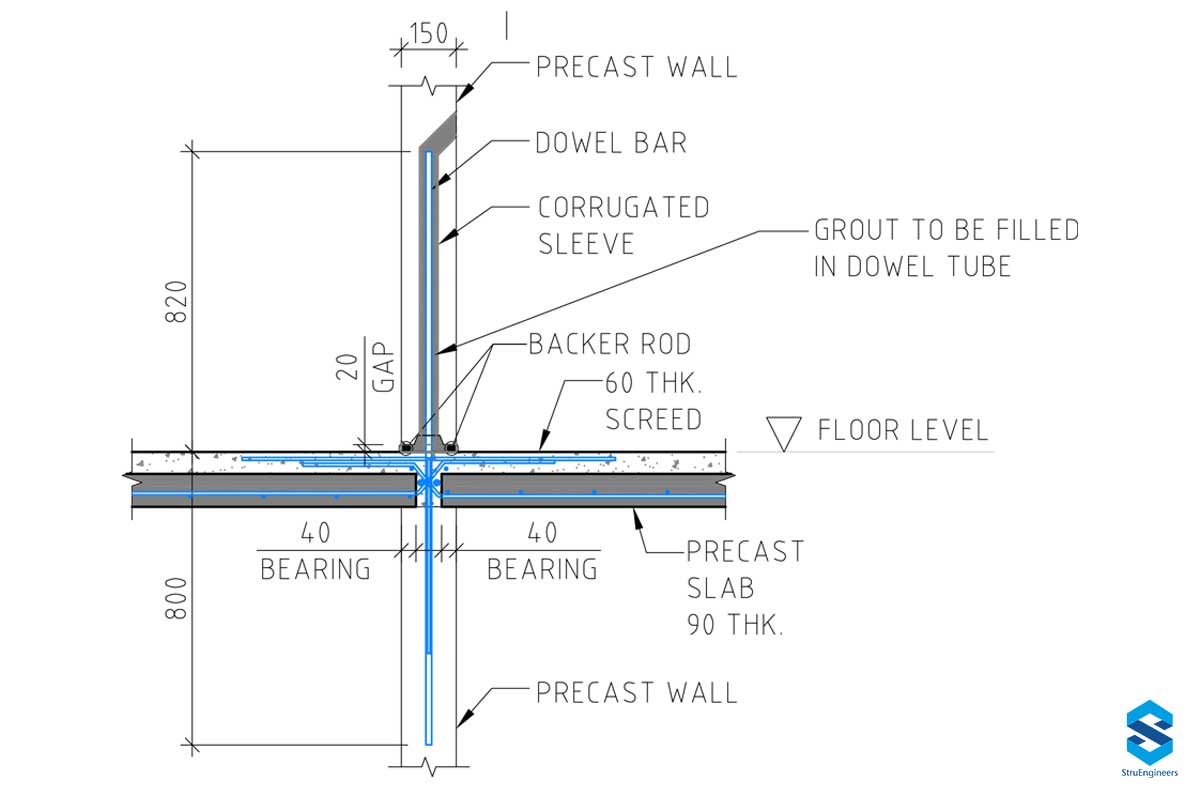

Precast joints

Advantages Offered by StruEngineers:

Precise Design and Detailing:

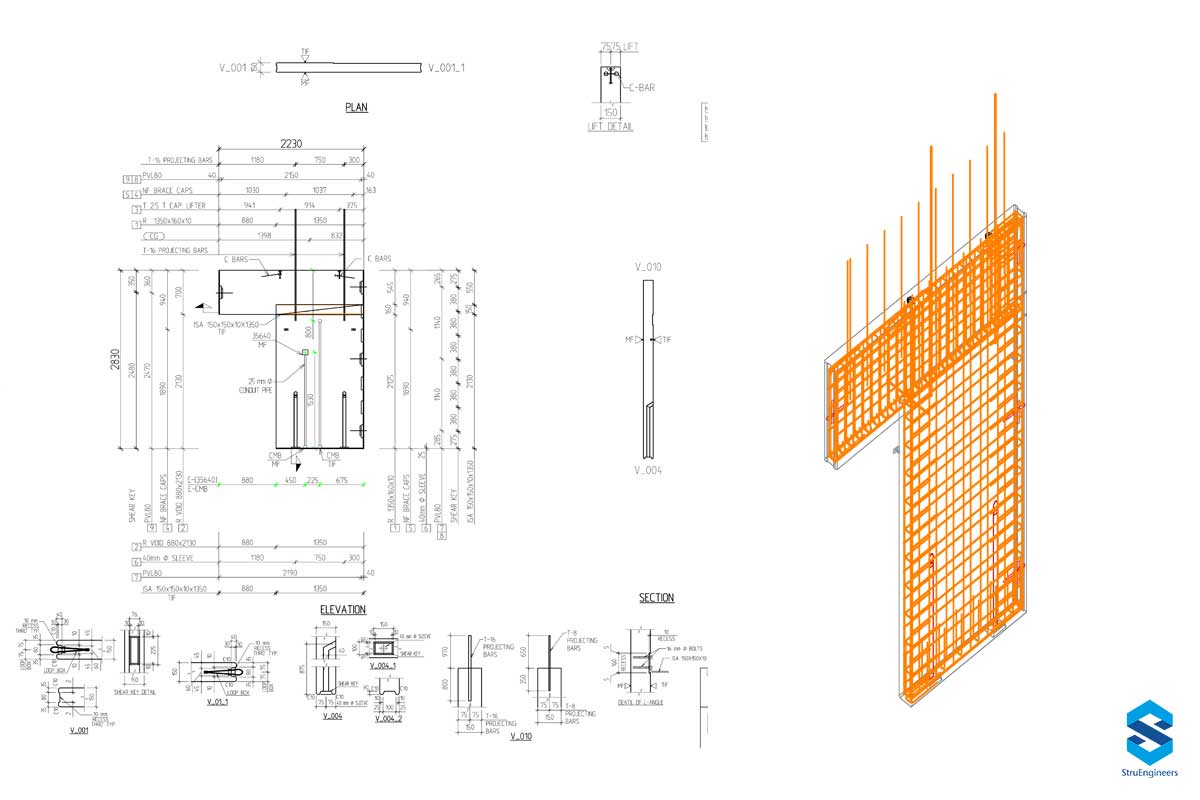

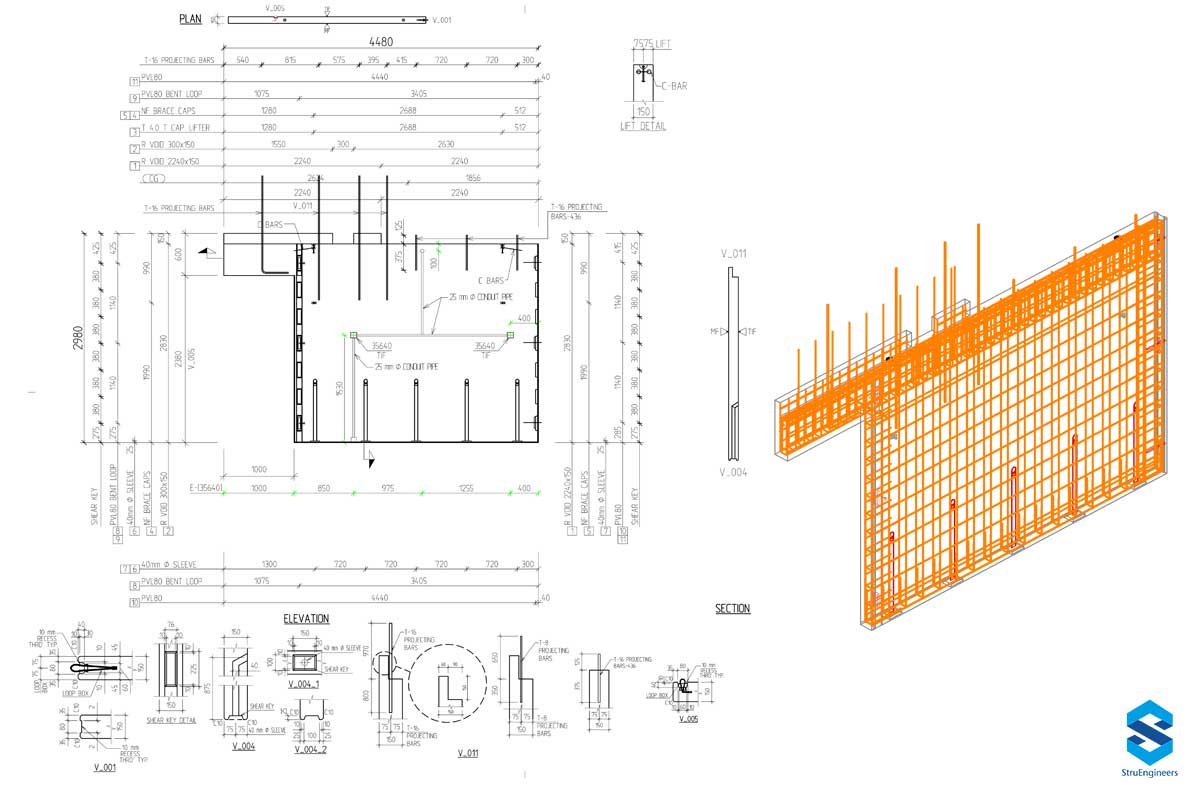

StruEngineers’ expertise in precast design and detailing played a crucial role in ensuring the success of the project. By utilizing the IMPACT BIM system, which facilitates accurate modelling and eliminates errors, StruEngineers provided a comprehensive and error-free design. This approach minimized rework, reduced construction time, and enhanced overall project efficiency.

Optimal Space Utilization:

The EWS housing project had limited available space, necessitating an efficient utilization strategy. StruEngineers’ precast design allowed for compact apartment layouts, with each floor accommodating 8 apartments ranging from 250 to 350 sq. ft. Integrating MEP systems into the precast walls further optimized space enabling seamless installation of electrical sockets and other utilities without compromising the apartment’s functionality.

Speedy Construction:

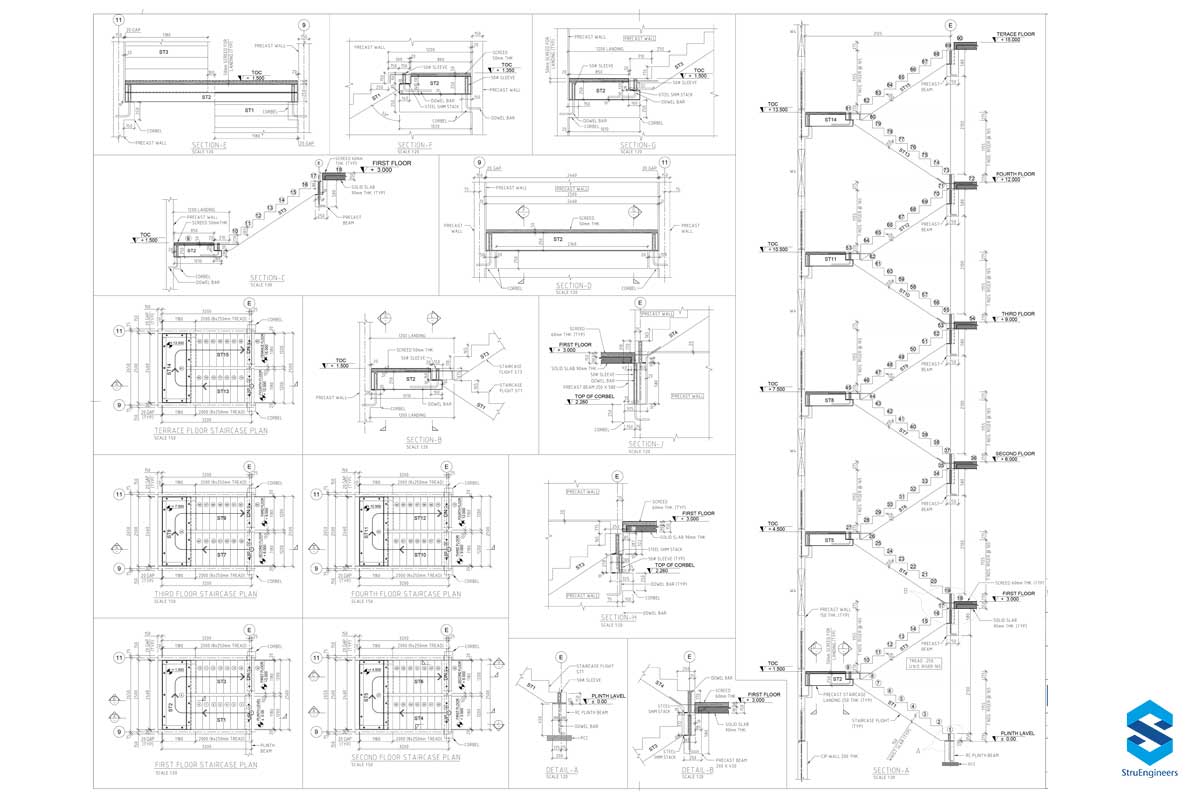

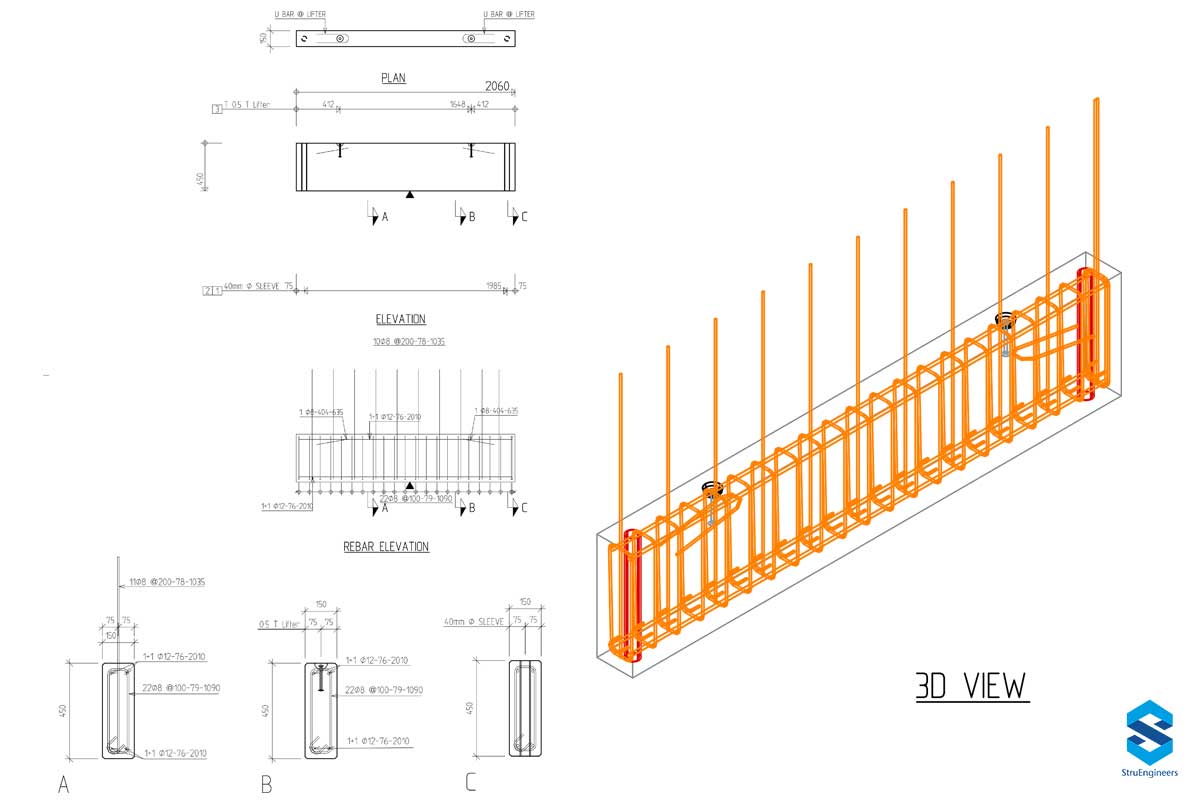

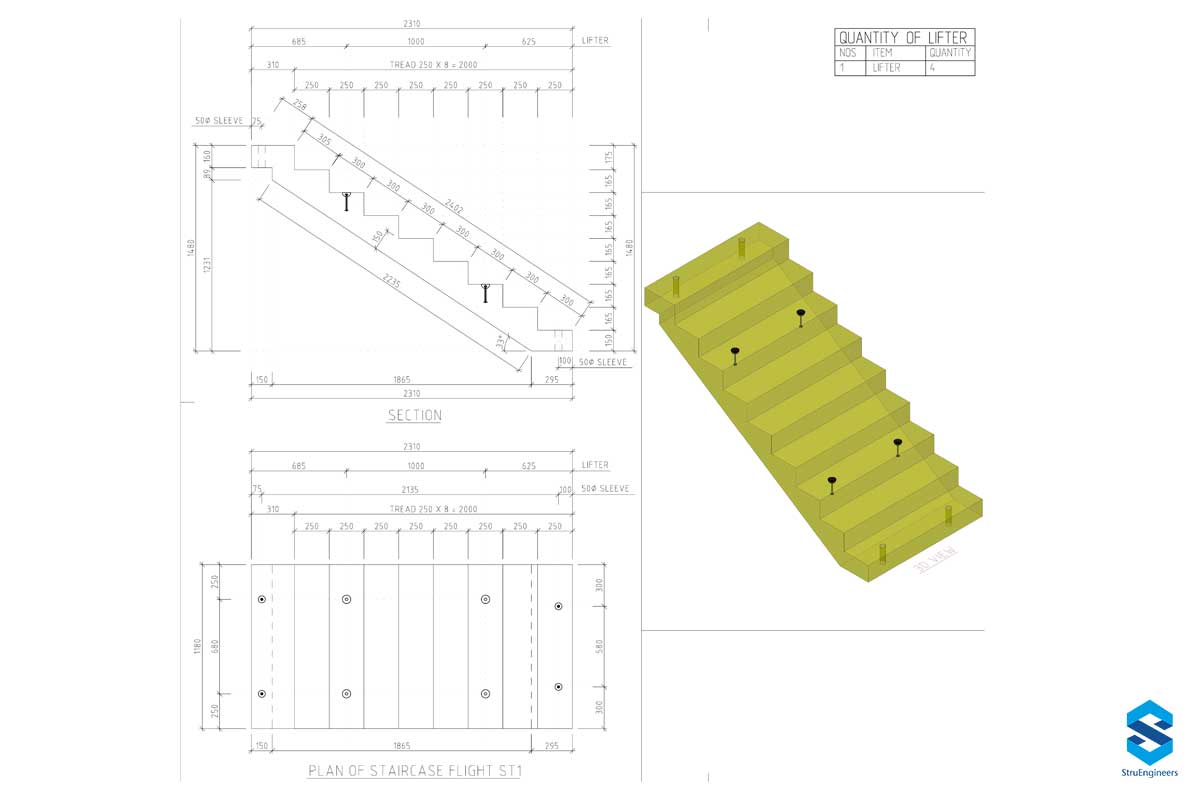

The project benefited by virtue of StruEngineers’ expertise & experience and the efficiencies offered by our BIM platform IMPACT. The precast elements, including load-bearing walls, half slabs, stair flights, and landing slabs, were manufactured off-site and the same time, the foundation and plinth work was being carried out at the site. It does not take much time to erect precast elements thereafter. This accelerated the construction process and facilitated timely completion of the project.

Enhanced Structural Performance:

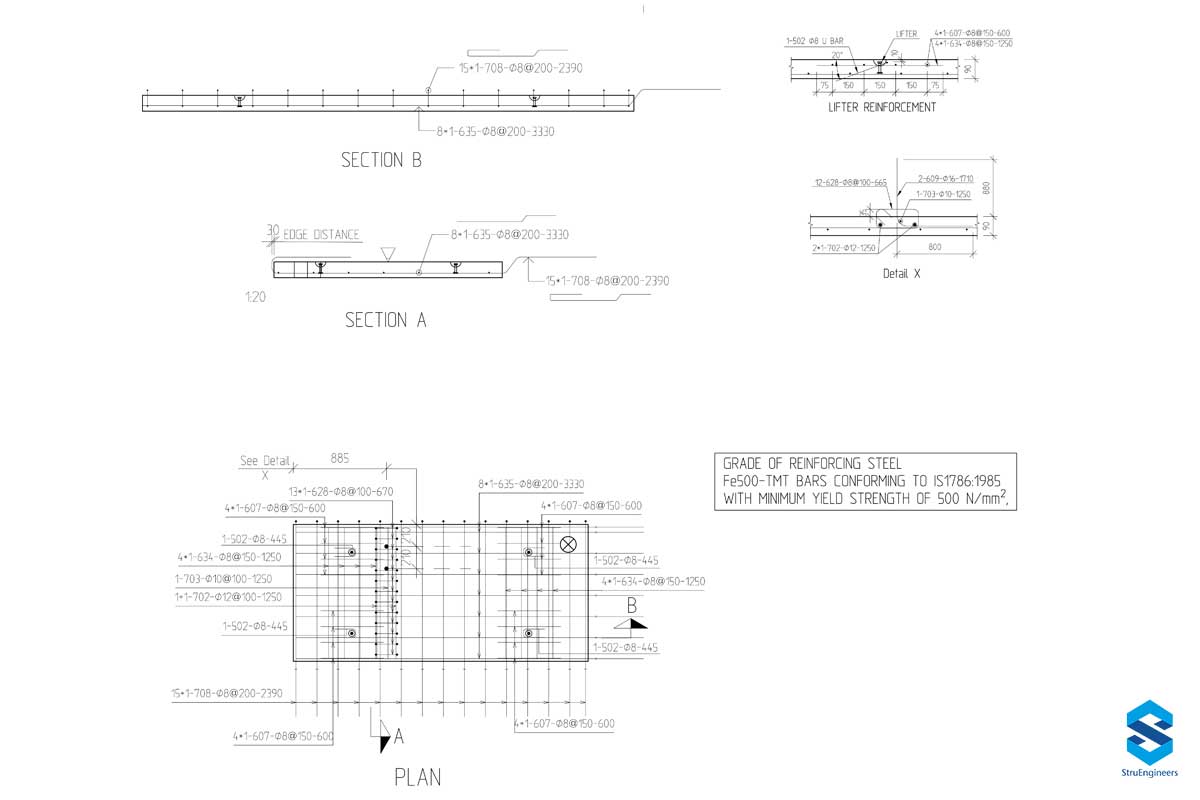

StruEngineers’ design approach, incorporating shear walls and precast half slabs, ensured a robust and structurally sound building. The 150 mm thick load-bearing walls, combined with 90 mm thick precast half slabs and 60 mm thick screed, provided sufficient strength and stability. The precast elements were designed to withstand the anticipated loads, ensuring the safety and longevity of the structure.

Improved Coordination and Collaboration:

Coordinating MEP systems with precast construction can present challenges. However, StruEngineers effectively managed this aspect by utilizing the IMPACT BIM system. By leveraging the IFC model, all stakeholders could collaborate seamlessly, resulting in improved coordination and minimized clashes between different building systems. This streamlined workflow reduced rework, avoided delays, and enhanced overall project efficiency.

Conclusion:

StruEngineers’ involvement in the precast design and detailing of the EWS housing project in Mumbai offered significant advantages to both the precast manufacturer and the end client. The precision and efficiency of the design, further aided by IMPACT BIM minimized errors and unnecessary repetition of work. The integration of MEP systems within the precast walls optimized space and enhanced functionality. Additionally, the use of precast elements allowed for faster construction, while ensuring structural integrity. StruEngineers’ expertise and innovative approach played a pivotal role in successfully delivering a cost-effective and high-quality housing solution for the Economically Weaker Sections in Mumbai.