Project Managers are spending too much time managing spreadsheets than managing the projects.

What if you could:

- Do away with spreadsheets

- Reduce time trying to find information

- Reduce errors from manually moving from one system to another

- Spend time actually managing your precast projects

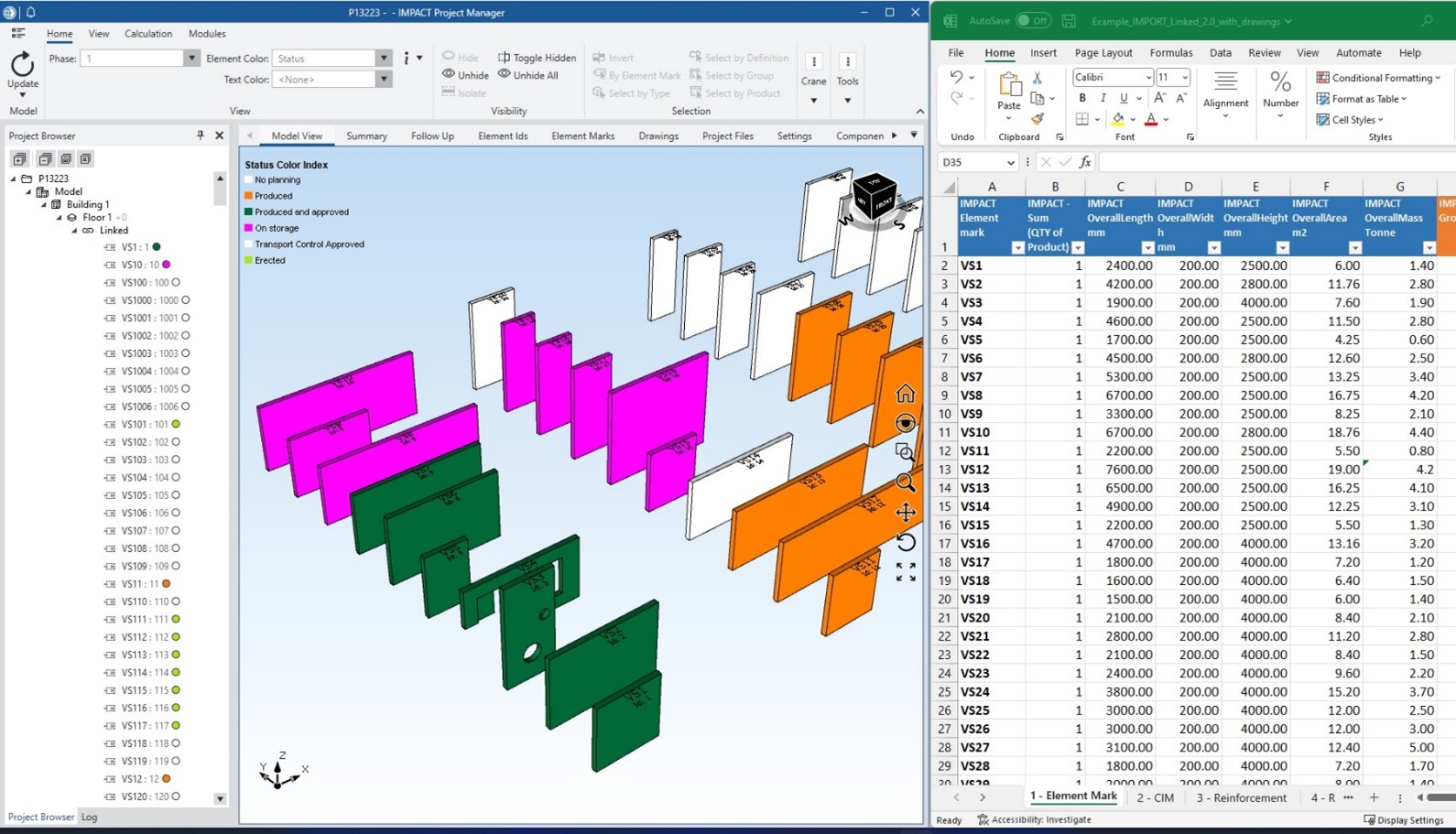

This article aims to apprise precast BIM users that in addition to designing & detailing of precast concrete elements, our BIM platform IMPACT can be leveraged for tracking and quality control of precast elements for infrastructure projects, such as Culverts, Sound Barriers, Railroad Sleepers, Tunnel elements, Girders, and Bridge Beams, in real time.

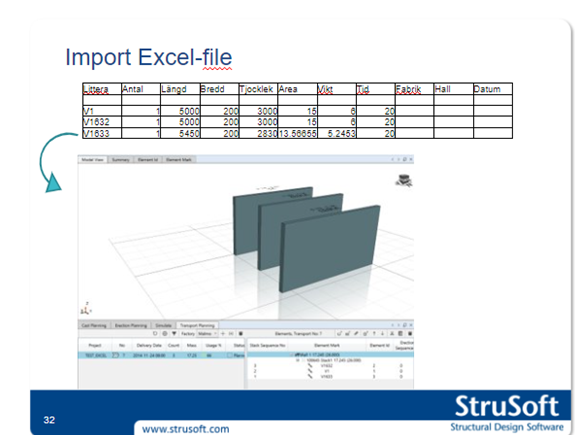

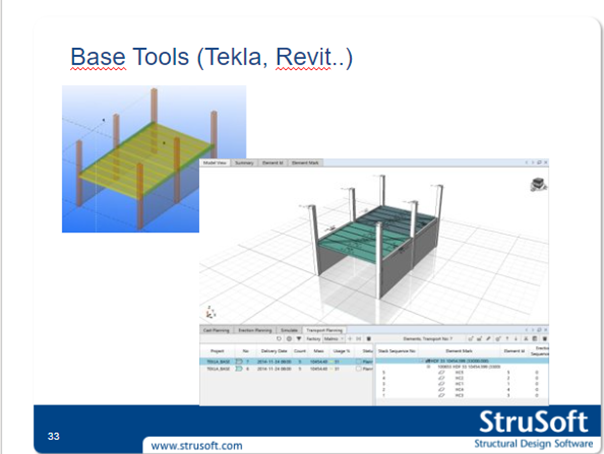

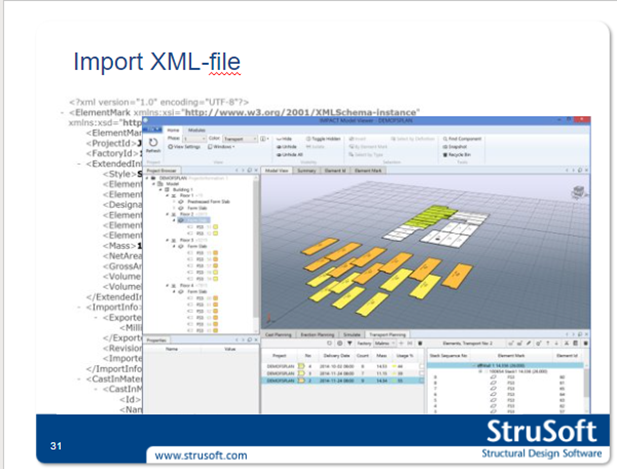

The beauty is that you can generate any standard or non-standard precast concrete elements used in infrastructure projects through inputs via Excel, XML, AutoCAD, and Tekla & Revit base tools

TRACKING

IMPACT has proven to be a valuable solution for precast manufacturers in the infrastructure sector. Through its real-time and cloud-enabled tracking feature, companies can easily monitor the status of precast elements, from production planning to transit to installation in constructed structures. This allows for efficient project coordination and improved visibility throughout the supply chain.

Tracking status

- Planned for production

- Produced

- Cast aside for repairs / rejected

- In transit

- Stored at site

- Part of a constructed structure

In the above image, you see that the elements are generated via input from Excel and the elements’ colors show their status.

Orange – Produced

Green – Produced & Approved

Violet – On storage

QUALITY CONTROL

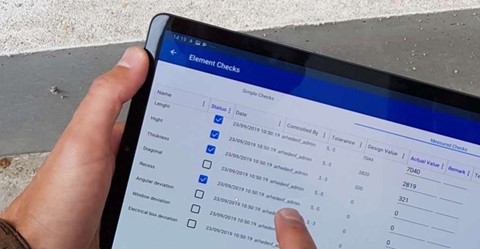

IMPACT’s quality control functionality enables precast manufacturers to define and track multiple parameters for each element, ensuring adherence to quality standards. In case of defects, users can quickly capture and upload photographs, assign responsibilities for rectification, and update the status in REAL-TIME. This streamlines the quality control process and facilitates effective communication among stakeholders.

Quality Control status (for production defects)

- Update disorders (defects) / rejects status to all relevant stakeholders in real time

- Take and update photos (multiple) in real time

- Assign responsibility and issue instructions using tablets and / or mobile phones with the IMPACT Go app

The precast concrete infrastructure elements can be defined in IMPACT by taking inputs from Excel, XML, AutoCAD, and Tekla as shown above, and the output can be given out in the same formats if required. IMPACT can integrate with ERP packages through SQL Open API or via XLS, XML or many precast industry data formats. The advantage of integrating this with ERP packages is that the production, tracking, QC and field operations of the precast infrastructure process is that it gels seamlessly with the overall company business operations.

Unlock the full potential of IMPACT for your precast infrastructure projects and experience streamlined tracking and quality control processes like never before!

FAQs: Enhancing Efficiency in Precast Infrastructure Projects with IMPACT

Yes, IMPACT can integrate with ERP packages through SQL Open API or via XLS, XML, and many precast industry data formats. This integration ensures that the production, tracking, quality control, and field operations of precast infrastructure seamlessly gel with the overall company business operations, enhancing efficiency and communication among stakeholders.

IMPACT’s quality control functionality enables manufacturers to define and track multiple parameters for each element, ensuring adherence to quality standards. In case of defects, it allows for quick capture and upload of photographs, assignment of rectification responsibilities, and real-time status updates, streamlining the quality control process.

Through its cloud-enabled tracking feature, IMPACT allows companies to monitor the status of precast elements in real-time, from planning and production to transit and installation. This feature improves project coordination and visibility, with element statuses visually represented in the system for easy identification.

IMPACT supports a wide range of standard and non-standard precast concrete elements used in infrastructure projects, including Culverts, Sound Barriers, Railroad Sleepers, Tunnel elements, Girders, and Bridge Beams. It allows for the generation of these elements through various inputs like Excel, XML, AutoCAD, Tekla, and Revit base tools.

IMPACT extends its capabilities beyond just design and detailing by incorporating advanced tracking and quality control features. It enables real-time monitoring of precast elements throughout the production, transit, and installation phases, ensuring efficient project coordination and enhanced visibility across the supply chain.