Construction projects can be complex and challenging to manage, with many different factors that must be taken into account. These days, a key element of successful construction projects is the use of BIM modelling services.

These services offer numerous benefits and solutions that can help maximize efficiency and ensure successful project outcomes.

In this blog post, we will explore some major benefits and the kind of solutions offered by BIM modelling services in the precast concrete industry .

What is BIM Modelling?

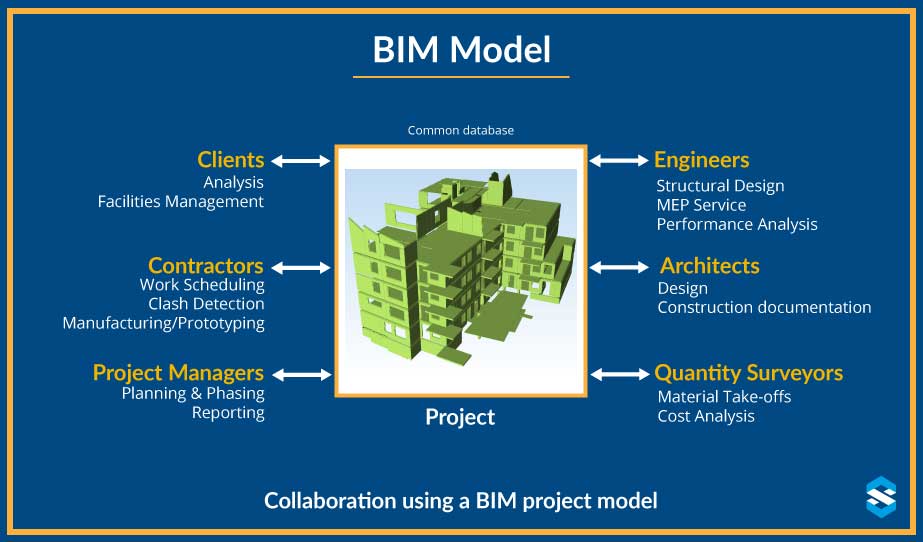

Before we dive into the benefits of precast concrete BIM modelling services, it is important to understand what BIM modelling is. BIM stands for Building Information Modelling and is a digital representation of a building’s physical and functional characteristics.

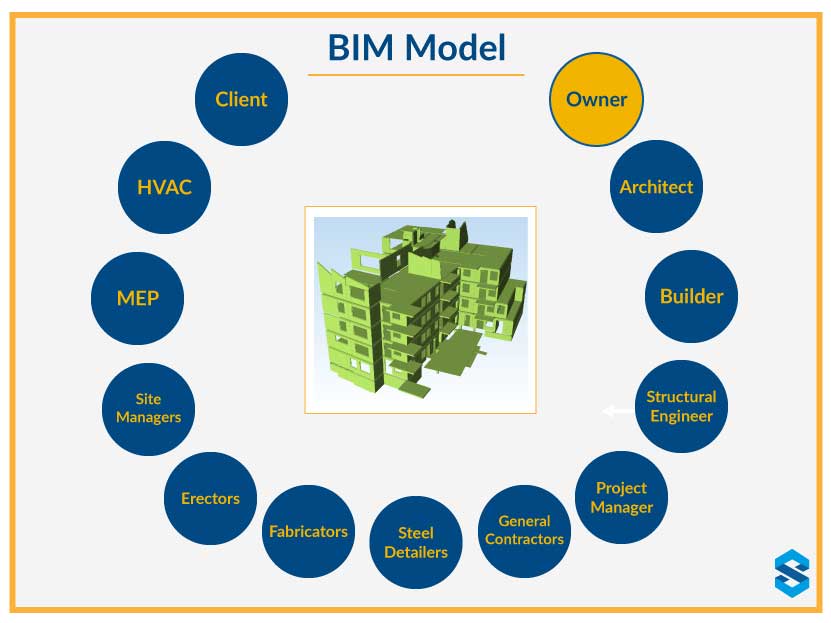

BIM models are created using specialized software that allows for the integration of data from various sources, including architectural, structural, mechanical, and electrical systems.

BIM models can be used throughout the lifecycle of a building project, from initial design to construction and maintenance. They allow for greater collaboration between different stakeholders and help to minimize errors and omissions.

BIM Modelling and the Precast concrete industry – A perfect collaboration

While BIM is useful for any construction method, the conventional cast-in-situ style of construction can still be managed without it for small projects.

Construction projects that use precast elements are very quick to build but require a high degree of precision and even a small error can lead to huge potential losses.

It would be therefore unwise to do without BIM modelling even for the smallest precast concrete projects. Let us look at some of the conveniences and efficiencies that BIM modelling offers to the precast concrete industry.

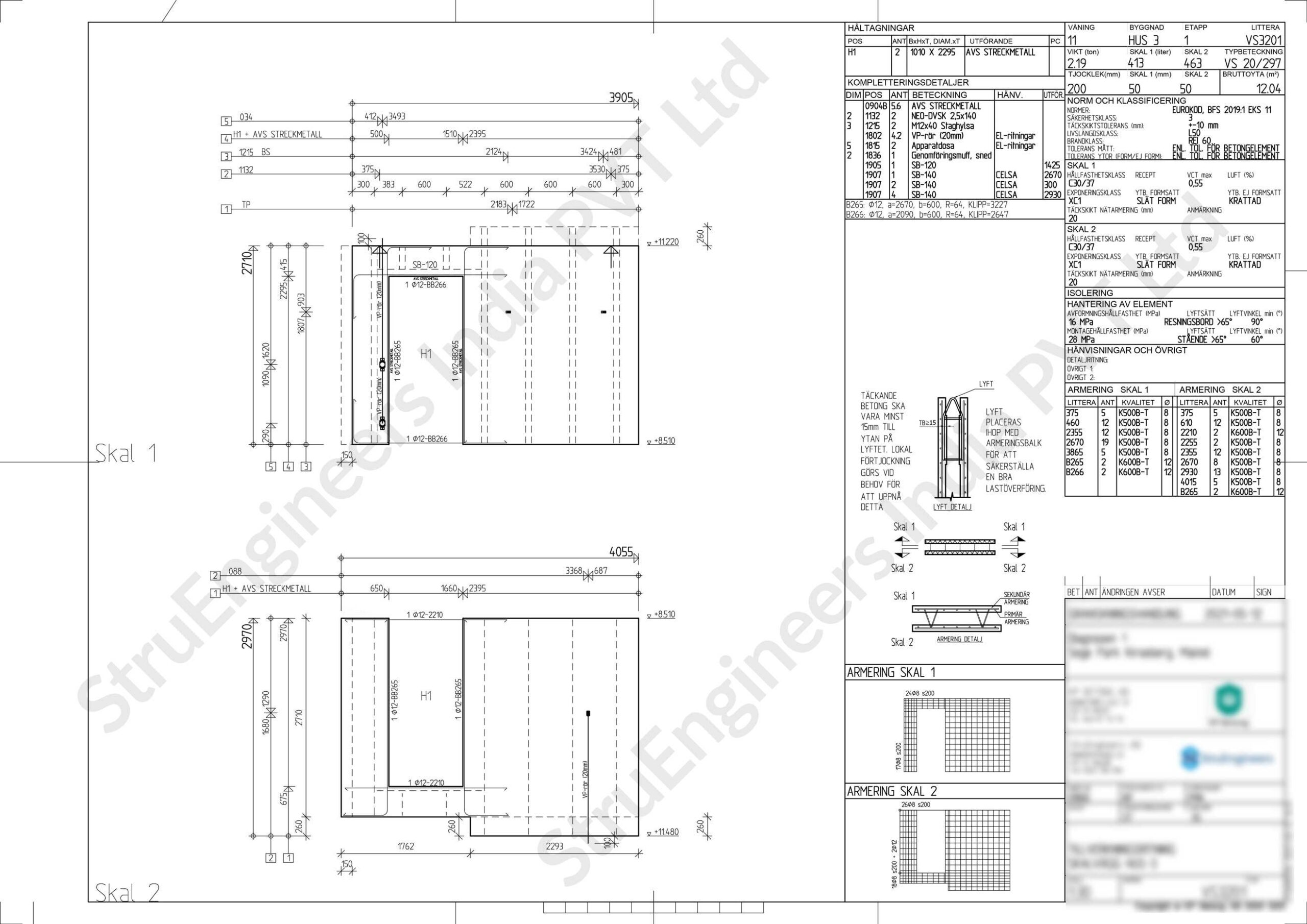

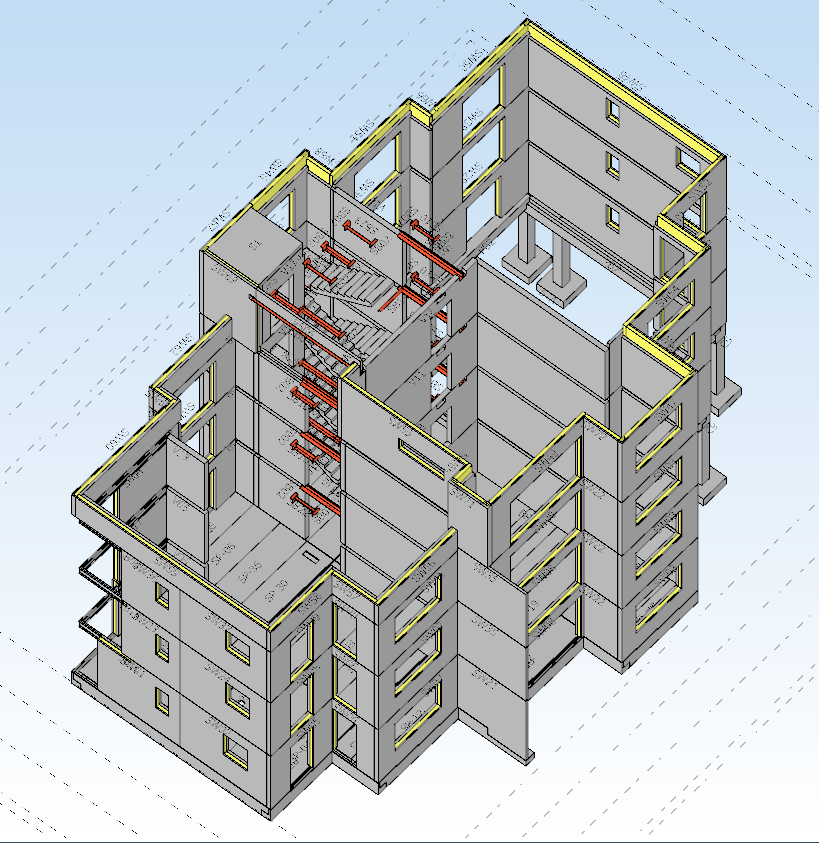

- During the design stage, BIM software platforms allow for the creation of detailed 3D models of precast elements, which can be reviewed and analyzed before they are manufactured. This ensures that any design flaws or issues can be identified and corrected early on, which can save time and money eventually.

- When manufacturing the precast elements, BIM modelling can help optimize production by considering factors such as crane capacity and cast bed size. By using BIM software, manufacturers can determine the most efficient way to produce and stack the precast elements, minimizing waste and maximizing the use of resources.

- Also, BIM software can be used to schedule production in a way aligned with the construction site’s requirements. This helps ensure that the precast elements are produced and delivered in a timely manner, which can prevent delays in the construction process.

- Once the precast elements are manufactured, BIM modelling can help with stacking sequence and transportation planning. By using BIM software to determine the crane capacity at both the factory and the construction site, manufacturers can avoid any potential issues or delays during transportation.

- Based on the truck carrying capacity and the crane capacity at the construction site, the BIM software can suggest the most efficient and the most cost-effective way to transport the precast element, minimizing the number of trips required and reducing transportation time and costs.

- Finally, BIM modelling can be used to plan the stacking of precast elements at the construction site, in a way that is aligned with the desired erection sequence. This helps ensure that the construction process is streamlined and efficient, which can save time and money for all parties involved.

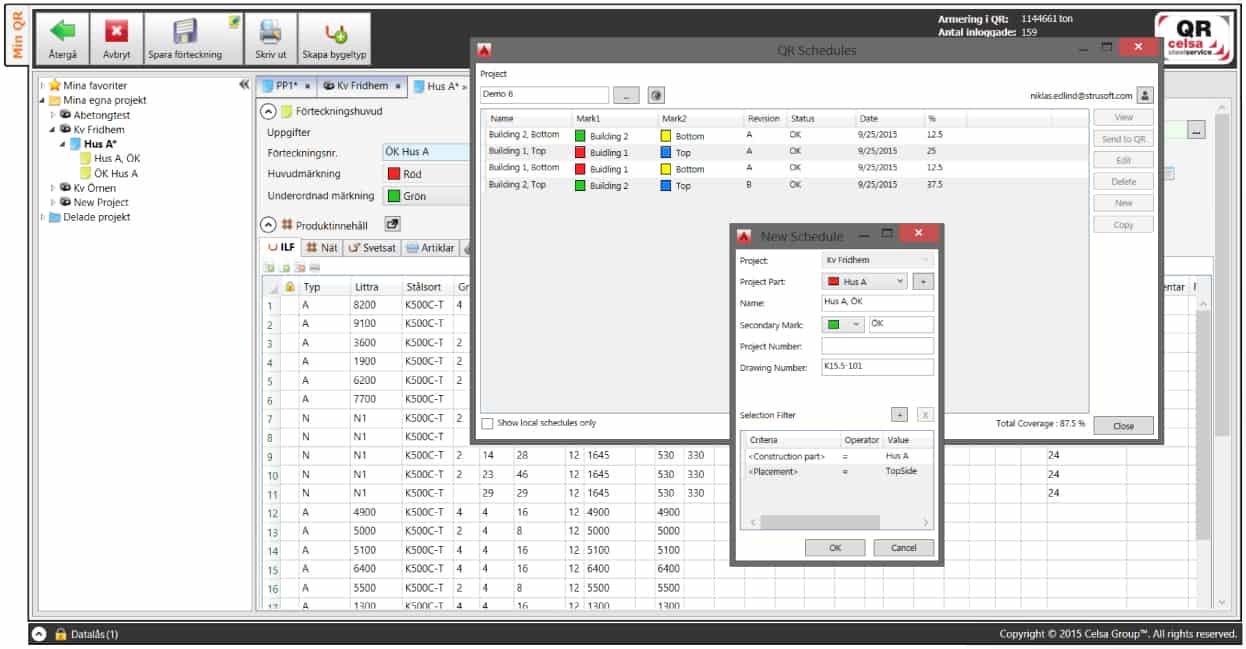

So, we see how BIM modelling is incredibly relevant to the precast concrete industry, as it helps optimize production and streamline the entire construction process. By using BIM software platforms, manufacturers can create detailed 3D models of precast elements, optimize production, schedule production in a way that is aligned with the construction site requirements, plan transportation and stacking sequence, and ensure that the erection sequence at the construction site is streamlined and efficient.

What are the other Benefits of Precast Concrete BIM Modelling Services

1. Improved Collaboration

One of the most significant benefits of using precast concrete BIM modelling services is improved collaboration between different stakeholders in a construction project. BIM models allow for the integration of data from various sources, including architectural, structural, mechanical, and electrical systems. This allows architects, engineers, contractors, and subcontractors to work together more effectively, reducing the risk of errors and omissions.

2.Increased Accuracy

Another key benefit of precast concrete BIM modelling services is increased accuracy. BIM models provide a detailed, 3D representation of a building, including all its components and systems. This allows for greater accuracy in design and construction, reducing the risk of errors and omissions. BIM models can also be used to simulate different construction scenarios, allowing for better decision-making and risk management.

3.Faster Construction

Using precast concrete BIM modelling services can also help to speed up construction projects. BIM models allow for greater collaboration and accuracy, reducing the need for rework and delays. This, in turn, can help to reduce project timelines and costs, improving overall project efficiency.

4.Improved Safety

BIM models can also help to improve construction site safety. By creating detailed, 3D representations of a building, including all its components and systems, BIM models can help to identify potential hazards and risks. This allows for better risk management and can help to reduce the risk of accidents and injuries on construction sites.

Solutions Offered by Precast Concrete BIM Modelling Services

1.Detailed Design

Precast concrete BIM modelling services offer detailed design solutions, allowing for greater accuracy and precision in the design process. This, in turn, can help to reduce errors and omissions and improve project outcomes.

2.Quantity Takeoffs

BIM models can also be used to generate accurate quantity takeoffs, allowing for more precise cost estimates and budgeting. This can help to ensure that projects are completed on time and within budget.

3.Clash Detection

BIM models can be used to detect clashes between different building components and systems, such as HVAC systems and structural elements. This allows for better coordination and collaboration between different stakeholders and reduces the risk of errors and omissions.

4.Construction Simulation

BIM models can also be used to simulate different construction scenarios, allowing for better decision-making and risk management. This can help to reduce project timelines and costs and improve overall project efficiency.

In conclusion, precast concrete BIM modelling services offer numerous benefits and solutions that can help maximize efficiency and ensure successful project outcomes. BIM models allow for improved collaboration, increased accuracy, faster construction, and improved safety. Precast concrete BIM modelling services offer solutions such as detailed design

FAQs: Enhancing Construction Projects with Precast Concrete BIM Modelling Services

The primary benefits include improved collaboration among project stakeholders, increased accuracy in design and construction, faster project completion, and enhanced safety on construction sites. These advantages lead to more efficient and safer construction projects.

BIM models create detailed 3D representations of buildings, helping to identify potential hazards and risks. This proactive approach to risk management can lead to safer construction sites by reducing the likelihood of accidents and injuries.

By fostering greater collaboration and ensuring higher accuracy, precast concrete BIM modelling services reduce the need for rework and delays. This efficiency can shorten project timelines and lower costs, enhancing overall project efficiency.

BIM modelling provides detailed, 3D representations of buildings, including all components and systems, which significantly increases design and construction accuracy. It also allows for the simulation of various construction scenarios, aiding in better decision-making and risk management.

Precast concrete BIM modelling services enhance collaboration by integrating data from architectural, structural, mechanical, and electrical systems into a unified model. This integration enables architects, engineers, contractors, and subcontractors to work together more effectively, minimizing errors and omissions.