Background

Our client Hi Therm Homes (HTH) restarted their precast factory after a long gap in operations and this was when the housing market in Ireland was witnessing a good surge in demand. HTH wanted to make the most of this opportunity and having their own precast manufacturing setup offered them a good head start.

To reduce turnaround time and improve efficiency, they decided to digitalize the complete manufacturing process and for this, StruSoft’s IMPACT BIM solution came up as a natural choice.

HTH does not have an in-house team for designing precast elements. As time was of essence, they did not want to go through the hassle of hiring new employees & training them and outsourced the precast elements design work to StruEngineers India.

The Setup

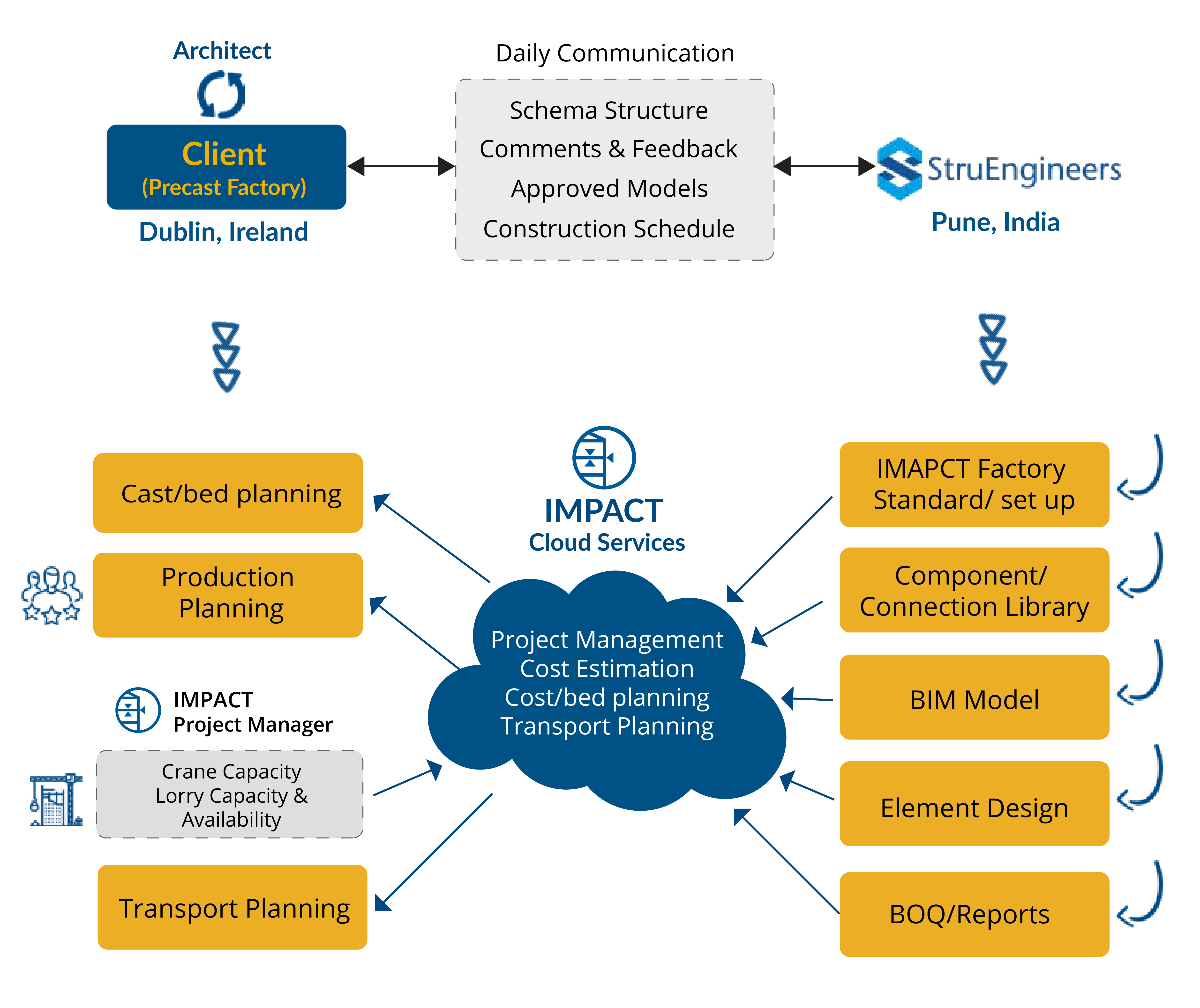

The overall arrangement worked out like this :-

- HTH did not have any BIM software so as a start, they shared architectural drawings with StruEngineers.

- After multiple rounds of discussions, the final approved model and construction schedule was shared by HTH.

- The Standard IMPACT BIM factory setup was done, and the component & connections library was set up. This would act as a base for the current and future projects.

- Then precast elements were designed, and the final BOQ & reports were prepared and shared with HTH.

Once this was done, HTH subscribed to the IMPACT BIM Production Module for further working at their end.

This module helped them with

- Production Planning

- Optimizing the casts /beds for manufacturing the precast elements

- Quality Analysis

- Planning transport of the precast elements to site

- Proper stacking sequence at site in tune with the construction plan

IMPACT BIM does all this automatically

The Outcome

The HTH team at Ireland and StruEngineers team in India had smooth, seamless, and hassle-free coordination over IMPACT BIM CLOUD. As a result, the project progressed as scheduled.

“StruEngineers’ professional approach & expertise obviated our need to have an in-house design team and dealing with the various HR challenges that would have come along with. IMPACT is highly feature-rich, and we intend to leverage it for maximum benefit. We have recently introduced robotic printers at our factory that run on the machine language output delivered by IMPACT”

Says….William Campion – Hi Therm Homes, Dublin, Ireland.

The biggest benefit to the client was that they were relieved of the hassle of finding & recruiting suitable designers, training them, tackling administrative issues that come along with hiring and dealing with employee turnover. They are happy with outsourcing precast design and detailing jobs to us and intend to continue with the arrangement. The client is impressed with the IMPACT BIM platform for precast with respect to its user-friendliness and its capabilities.

Our Design Expert Mangesh Dhumal summarizes his experience very aptly

“Coordinating a construction project from two separate locations is like preparing a recipe with ingredients being added from two different kitchens and then cooking them together in a common cauldron (in this case, our IMPACT BIM Cloud)”