StruEngineers India Pvt Ltd was engaged by a major Irish housing developer to provide comprehensive precast detailing and 3D BIM modeling services for their large-scale residential projects. As the client embraced off-site construction to overcome industry challenges, our role was to provide the critical technical expertise needed to transition their architectural designs into manufacturing-ready precast models, ensuring accuracy, speed, and seamless coordination from the design phase to on-site assembly.

The Challenge

The Irish construction sector faced two significant hurdles: a persistent skilled labor shortage and intense pressure to accelerate housing delivery. Our client aimed to address these issues by industrializing their construction process through precast technology. The primary challenge was to efficiently and accurately convert traditional architectural plans—originally conceived for conventional blockwork—into fully detailed, coordinated, and manufacturable precast systems. This required a specialized skillset to re-engineer designs and ensure every element was optimized for factory production and rapid on-site assembly.

StruEngineers’ Solution

Our team acted as a dedicated, integrated design partner, providing end-to-end precast detailing solutions. We established a collaborative workflow to transform the client’s vision into a precise digital blueprint for construction.

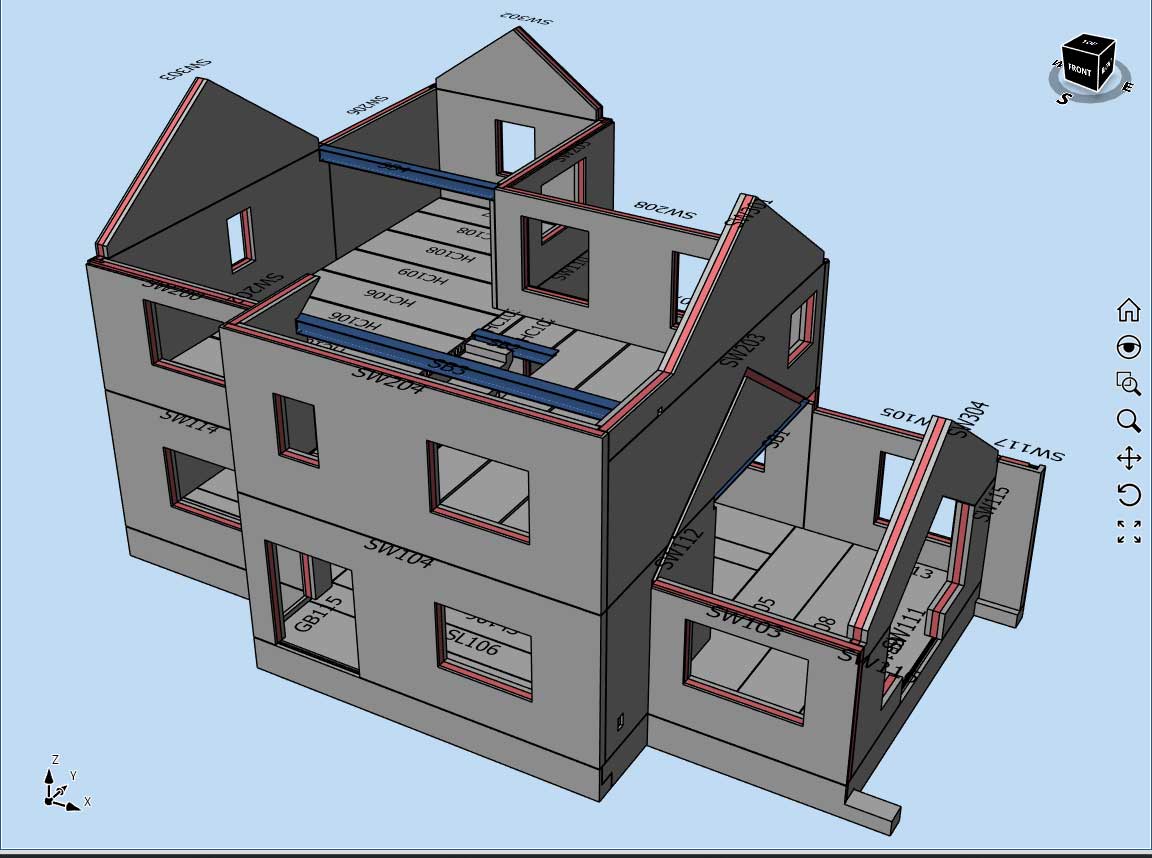

- Collaborative Design Adaptation: We worked in close partnership with the client’s engineers and architects. Our first step was to analyze the traditional layouts and strategically adapt them for precast suitability, identifying opportunities for standardization and improved buildability without compromising the architectural intent.

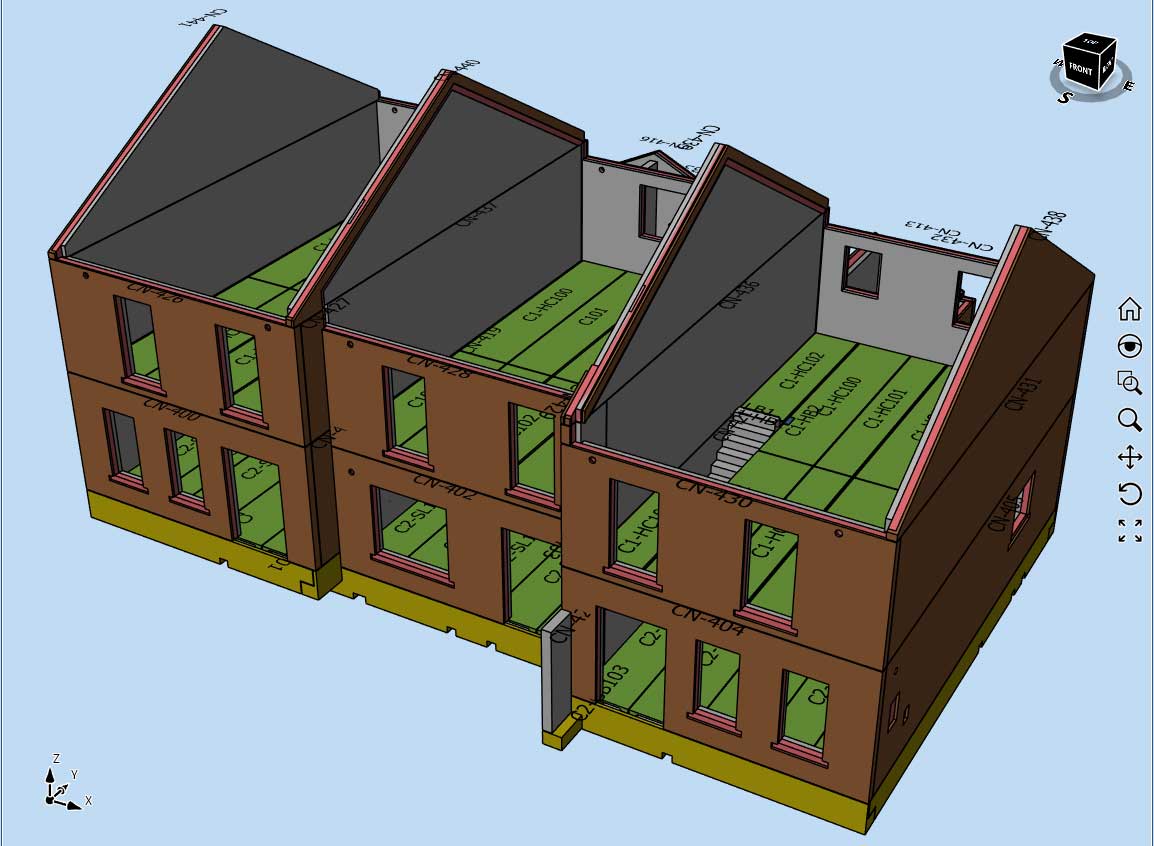

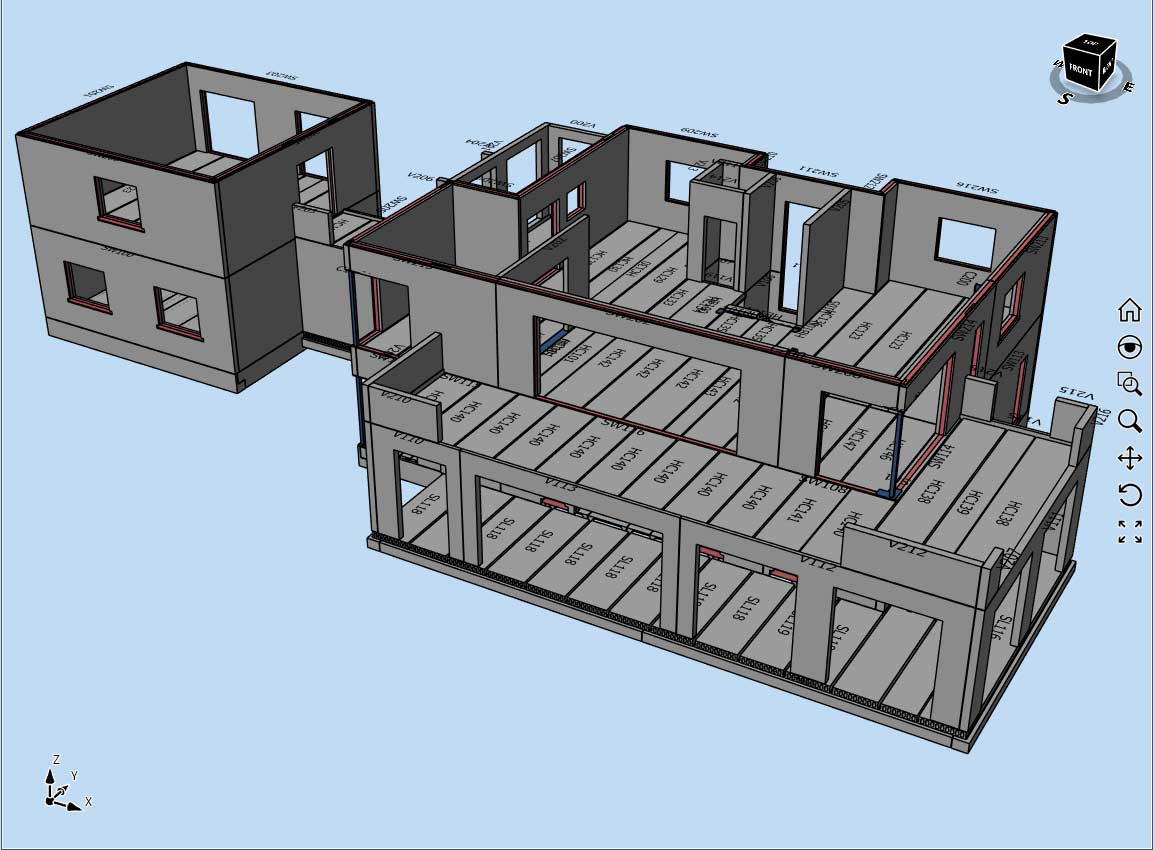

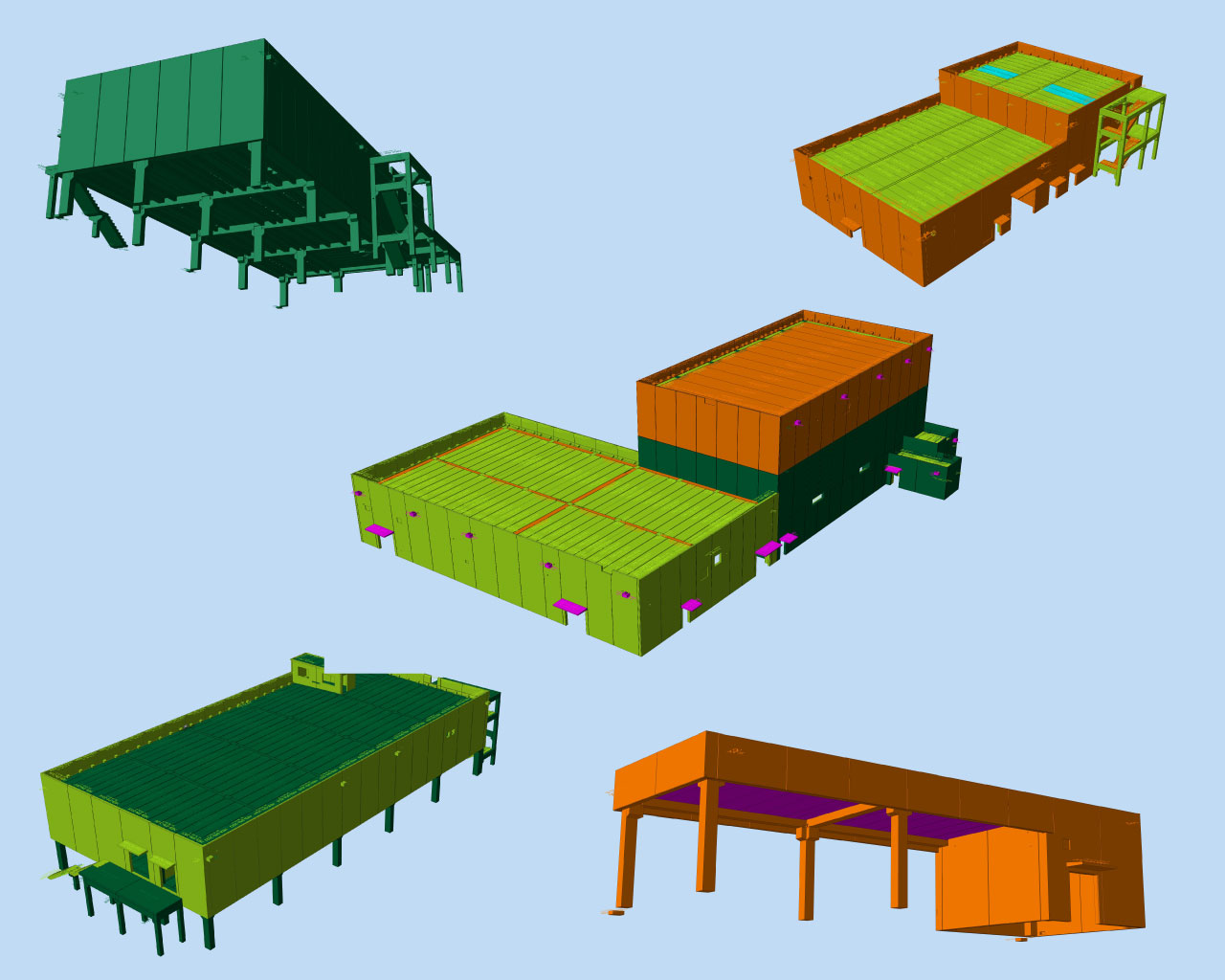

- Detailed 3D BIM Modeling: Using advanced BIM software, we created a comprehensive and intelligent 3D model for each housing unit. This model served as the single source of truth, containing precise details for every precast component, including: * Insulated Sandwich Walls * Solid Concrete Walls * Hollow-Core Floor Slabs * Foundation Beams and Structural Elements

- M&E Service Integration: To maximize off-site prefabrication, we meticulously embedded all Mechanical, Electrical, and Plumbing (MEP) openings, conduits, and cutouts directly into the precast element designs. This level of detail minimized on-site manual work and prevented clashes.

- Automated Shop Drawing Generation: From the finalized and approved BIM model, we automated the generation of all necessary shop drawings. This process ensured an exceptional level of accuracy and consistency across hundreds of drawings, providing the factory with clear, error-free instructions for manufacturing.

- Seamless Stakeholder Coordination: The detailed models were shared as IFC files, facilitating seamless coordination between the client, their structural engineers, and architectural agencies. This digital workflow ensured all parties were aligned, and that feedback was captured and integrated efficiently.

Key Services Provided

- 3D BIM Modeling for Precast Structures

- Precast Concrete Detailing & Shop Drawing Generation

- Conversion & Optimization of Traditional Designs for Precast Manufacturing

- Mechanical & Electrical (M&E) Service Integration

- Clash Detection and Resolution

- BIM Coordination and Management

Tools & Technologies Used

- Tekla Structures (with Precast Concrete Detailing capabilities)

- AutoCAD

- Industry Foundation Classes (IFC) for collaboration

- Microsoft Teams for daily communication and project management

Results & Outcomes

Our partnership and technical services delivered significant value to the client, directly contributing to the success and scalability of their off-site construction initiative.

- Accelerated Timelines: The detailed, manufacturing-ready models and drawings drastically reduced the lead time from design to production.

- Enhanced Accuracy: Automation and BIM coordination minimized human error, leading to precise manufacturing and eliminating costly rework on site.

- Streamlined Coordination: The use of a central 3D model created a single source of truth, improving communication and decision-making for all project stakeholders.

- Enabled Scalability: By providing a reliable and efficient detailing workflow, we empowered our client to overcome labor shortages and confidently scale up their housing production to meet market demand.

Partner with StruEngineers for Your Precast Project

This project demonstrates our deep expertise in precast detailing and our commitment to driving innovation in the construction industry. If you are looking to leverage the power of off-site construction, our team has the skills and experience to ensure your project’s success.