- KPMG-NAREDCO report suggests that by 2030 India could be the world’s third-largest global construction market.

- In a single financial year, India is investing around $ 81.78 Trillion for developing and upgrading infrastructure.

- In just 3 years UK has saved over $ 2 Billion by mandating the use of BIM in public sector projects.

- The Top 100 Contractors across the globe operate at profitability of just 1.5%.

Well, this is just the beginning.

Over decades and centuries, technology has not only made things simpler but has helped to save trillions of dollars in everything we do. From the world’s thinnest laptops to the world’s largest aircraft, technology has touched every aspect of our life. Companies and industries that have kept pace with technology are the ones that are successful today.

In the case of precast construction industry, technology has revolutionized the industry and has changed the way construction is taking place across the globe. However, there is still a big gap between the methods adopted by precast manufacturers, precast construction companies and the available technology in the industry. A big gap also means there is immense potential, for not only streamlining the construction processes, but also saving a great amount of money. Adapting the right technology can help precast factories and precast builders to save time and cost and enhance their profitability.

Why should the construction industry adopt BIM for precast in India ?

Of late, Building Information Modelling (BIM) is gaining popularity worldwide, and more so in India. Companies engaged in the precast construction business are embracing BIM, for both public and private sector construction projects.

In case, if you are not aware of what BIM is, let us understand it quickly, especially from the precast industry perspective. In simple words, BIM can be defined as a multi-dimensional graphical representation of the precast manufacturing process and precast construction projects. It helps to build virtually before building physically, enabling different stakeholders in the construction project to get a feel of and understand the physical and intrinsic features of the project.

The BIM approach is helpful because it helps in understanding and eliminating issues that may arise in the precast design, precast detailing, precast production, and the precast construction phase. When the three dimensions of BIM are combined with parameters such as cost, time, and project lifecycle management, it creates a six-dimensional model and serves as a point of reference for all stakeholders in the precast business. BIM approach takes the architects, engineers, and builders from the industry miles ahead as they can execute the work more efficiently by eliminating or significantly minimizing the obstacles that may arise during the manufacturing, and construction process.

Some of the keywords that define Building Information Modelling (BIM) are:

- Efficient execution

- Project lifecycle management

- Multidimensional approach

- Cost control

- Timely execution of projects

- Better coordination

- Future-ready

Elevate Your Precast Projects with Industry-Leading BIM Services offered by StruEngineers

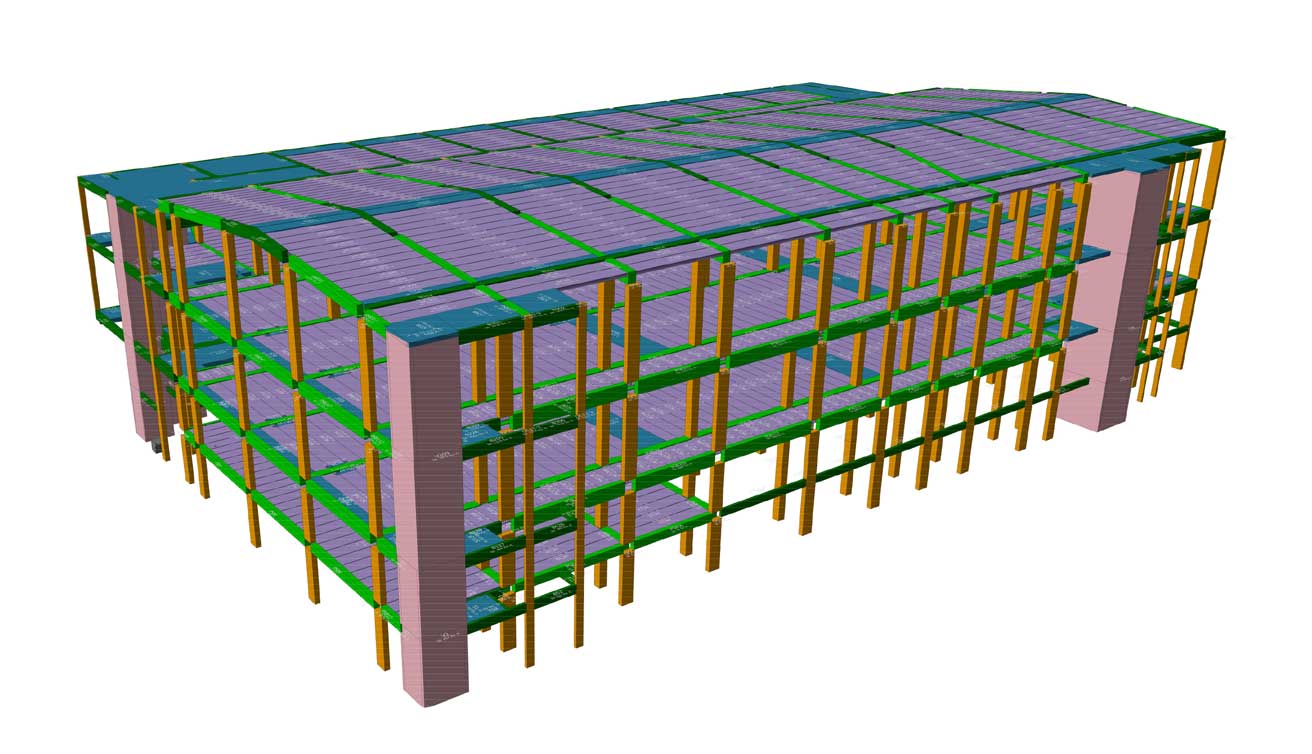

Modelling

- Detailed 3D Modeling of Precast Elements: This includes accurate modeling of individual precast components like walls, beams, columns, hollo core slabs, and stairs, incorporating specific information like reinforcement, embedded items, connections, and finishes.

- Shop Drawing Generation: Automatically generate accurate 2D shop drawings directly from the 3D models, minimizing errors and saving time.

- BIM Families for Standardization: Create reusable, parametric families of precast elements for improved efficiency and consistency across projects.

Design and Analysis

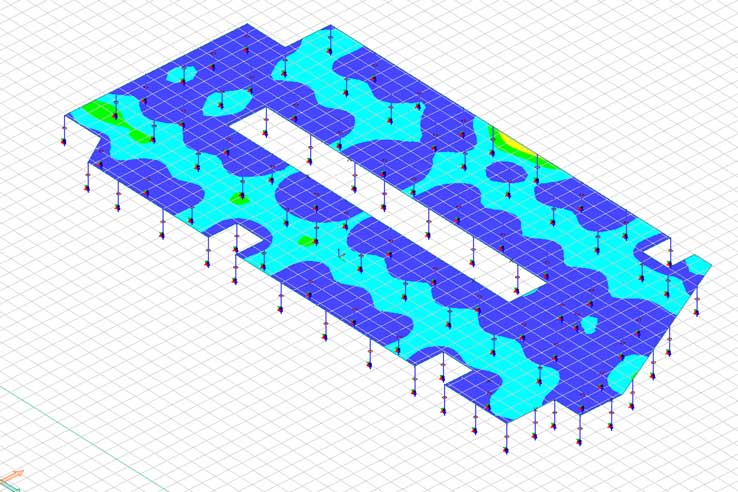

- Finite Element Analysis (FEA) for Precast: Perform load-bearing and structural analysis of precast components within the overall BIM model, optimizing design performance.

- Connection Design and Detailing: Detailed modeling and analysis of connections between precast elements and other building components.

- Lifting and Erection Planning: Integrate lifting plans and rigging details into the BIM model for safe and efficient erection.

Production Planning and Optimization

- Production Scheduling and Sequencing: Utilize the BIM model to optimize production schedules, considering lead times, resource availability, and logistics.

- Material Take-Off and Ordering: Automatically extract material quantities and specifications from the model for accurate ordering and cost estimation.

- Quality Control and Inspection: Develop BIM-based inspection checklists and workflows for quality control at the precast facility.

Collaboration and Communication

- Clash Detection and Resolution: Identifying and resolving potential clashes between precast elements and other building components early in the design phase.

- Real-Time Visibility and Collaboration: Share and collaborate on the BIM model with precast manufacturers, erectors, and other stakeholders for improved coordination and communication.

- Data-Driven Decision Making: Leverage BIM data for informed decision-making throughout the precast workflow, from design to erection.

FAQs: The Imperative for BIM Adoption in India’s Construction Industry

While BIM is particularly advantageous for large and complex projects due to its ability to manage intricate details and coordination among numerous stakeholders, its principles and technologies can also be applied to smaller projects. BIM’s scalability allows for its adoption across a wide range of project sizes, offering similar benefits of efficiency and cost-effectiveness.

By enabling virtual construction and facilitating early detection and resolution of potential issues, BIM significantly reduces the need for rework, delays, and cost overruns. This preemptive approach to project management ensures that projects are completed on time and within budget.

BIM offers numerous benefits, including efficient project execution, enhanced project lifecycle management, a multidimensional approach to construction planning, improved cost control, timely project completion, better stakeholder coordination, and preparation for future project demands and challenges.

The adoption of BIM in India’s construction sector promises significant advancements in efficiency, cost control, and project lifecycle management. It enables better coordination among all project stakeholders, ensuring timely project execution and future readiness, thereby enhancing overall profitability and success.

BIM is a multi-dimensional graphical representation process that enhances the planning, design, construction, and management of buildings and infrastructure. Particularly in the precast industry, BIM facilitates virtual construction, allowing stakeholders to visualize and address potential issues in design, detailing, production, and construction phases before physical work begins.