We are living in an era where the “brick and mortar” industry is entering into the digital age. Digitalization is not just accelerating the construction industry, but it is also helping cope with factors that are driving change in the construction industry, such as:

If we talk about the precast industry, digitalization is playing a significant role in integrating design and production in precast factories. From the flow of information to the speed of reaction, digitalization plays a role everywhere. It is not only making processes easier, but is also ensuring better control and integration; thereby resulting in better efficiency and cost savings.

At StruEngineers, our team of experts is serving clients in 30 countries across the globe, with our in-house software “IMPACT”, built by our Sweden-based holding company StruSoft AB. We are happy to share that, StruSoft and StruEngineers have played a key role in the digitalization of the construction industry over the last 35 years, by offering industry-leading software for Design, 3D BIM Modelling, and Production Management.

IMPACT is one of the leading software in the precast concrete industry and provides state-of-the-art tools required to implement a BIM workflow and manage every aspect of the precast concrete business – whether it is design, production, or projects, all in 3D. To cater to the design and production needs of the precast concrete industry, IMPACT comes with two different modules:

- IMPACT Design

- IMPACT Production

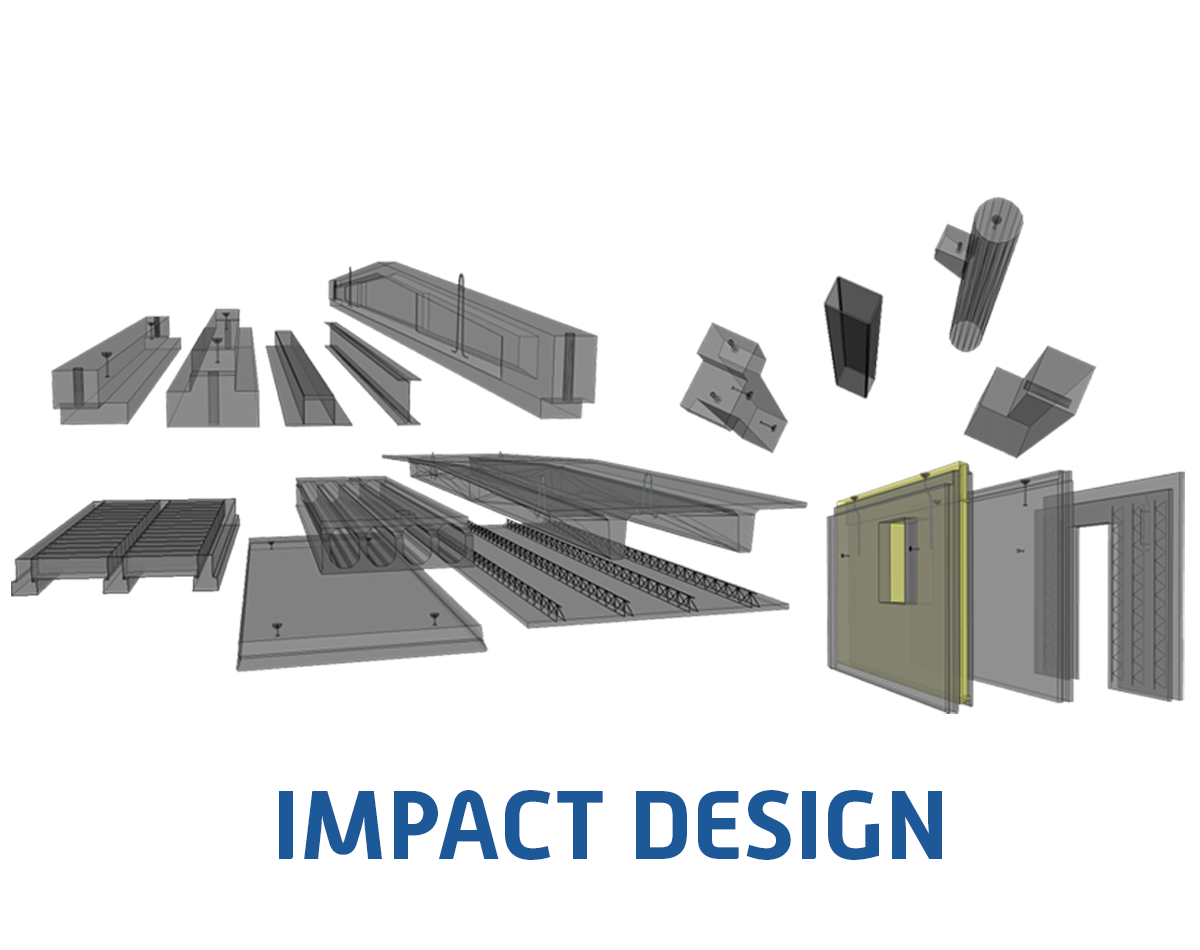

IMPACT Design

IMPACT Design provides the tools needed to implement a BIM workflow in your detailing department. It lets you manage every aspect of precast concrete detailing; 3D modelling and even provides tools for rough planning and erection planning, through the integrated Project Manager.

With nearly unlimited possibilities for customizing the software through company standards, IMPACT Design can be tailored to exactly fit your precast concrete requirements.

| IMPACT Design Features: | Advantages: |

|---|---|

| Automatic Shop Drawings | Reduce manual layout errors |

| Company Standards | Standardise your design workflows |

| Full 3D modelling | Minimise design errors |

| Automatic Dimensioning | Speed up your design and detailing |

| Rebar Templates | Automatic rebar detailing |

| AutoCAD, BricsCAD, Revit, Tekla® | Integrate with industry software |

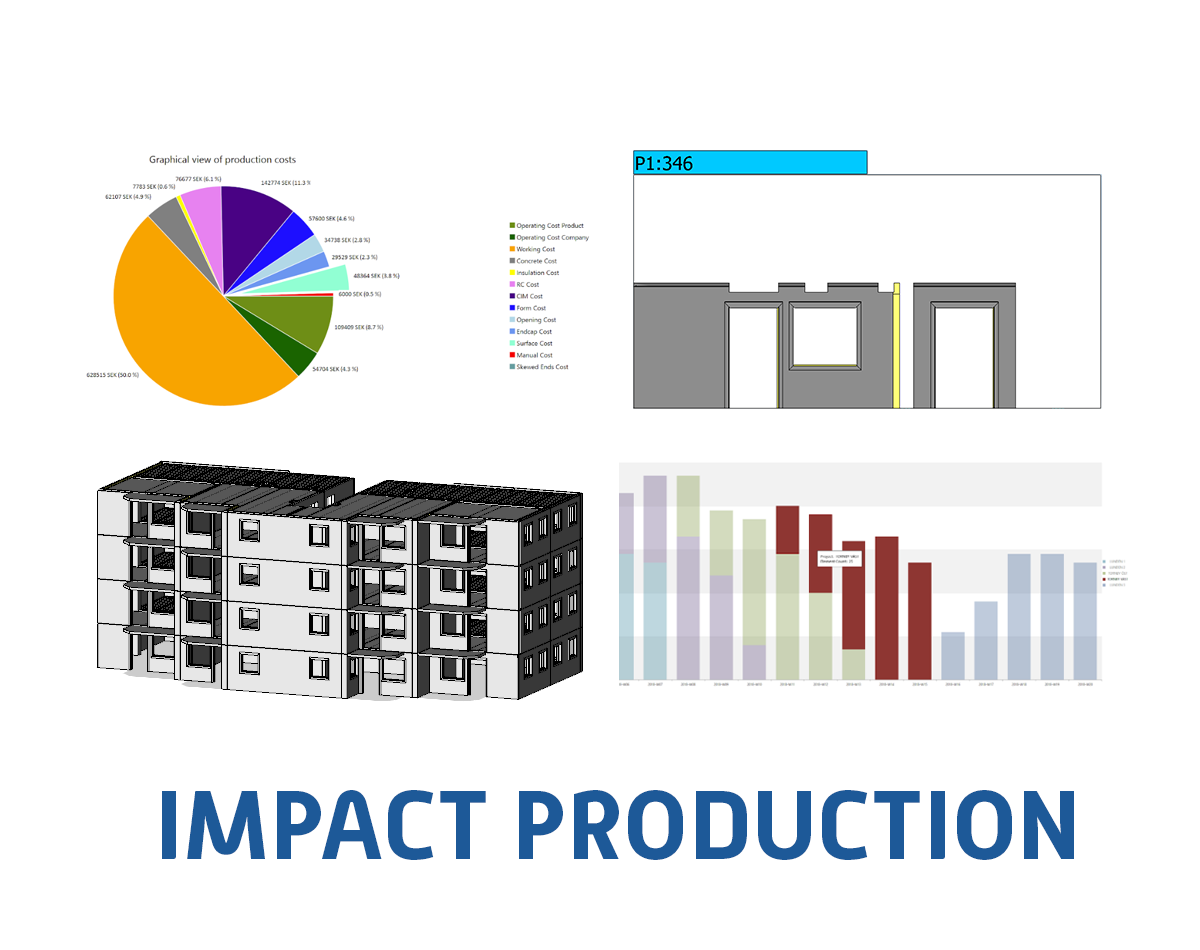

IMPACT Production

IMPACT Production provides the tools needed to implement a complete BIM workflow and manage every aspect of precast elements design and precast production planning.

The software is highly customizable to the exact needs of your precast factory; offering you the ability to 3D plan and keep better track of all types of precast elements; individual and multiple projects.

| IMPACT Production Features | Advantages |

|---|---|

| Resource Manager | Plan multiple projects from any factory |

| 3D Project Manager | Visually manage a precast project |

| 3D Cast Planner | Utilize your production capacity smartly |

| Transport Planner | Optimize your transportation of precast elements as per crane and truck capacity |

| Element Control | Keep track of every precast element |

| IMPACT Go | Access real-time data from anywhere |

FAQs on Digitalization Advantages in the Precast Concrete Industry: IMPACT Design and Production

Digitalization ensures higher quality and consistency in precast concrete elements by standardizing processes, automating quality checks, and providing detailed documentation. This reduces human error and ensures that all elements meet the required specifications and standards.

Digitalization fosters better collaboration by enabling real-time data sharing and communication among all stakeholders, including designers, manufacturers, and contractors. This integrated approach ensures everyone is on the same page, reducing misunderstandings and project delays.

The IMPACT Production module optimizes production planning and execution. It provides real-time tracking, quality control features, and detailed production scheduling, enhancing overall productivity and minimizing waste in the manufacturing process.

IMPACT Design software facilitates precise and efficient design of precast concrete elements. It offers advanced modeling capabilities, automated detailing, and seamless integration with production processes, ensuring high-quality outputs and reduced design time.

Digitalization in the precast concrete industry enhances efficiency, accuracy, and collaboration. It streamlines design processes, improves production planning, and reduces errors, leading to significant cost savings and faster project completion.