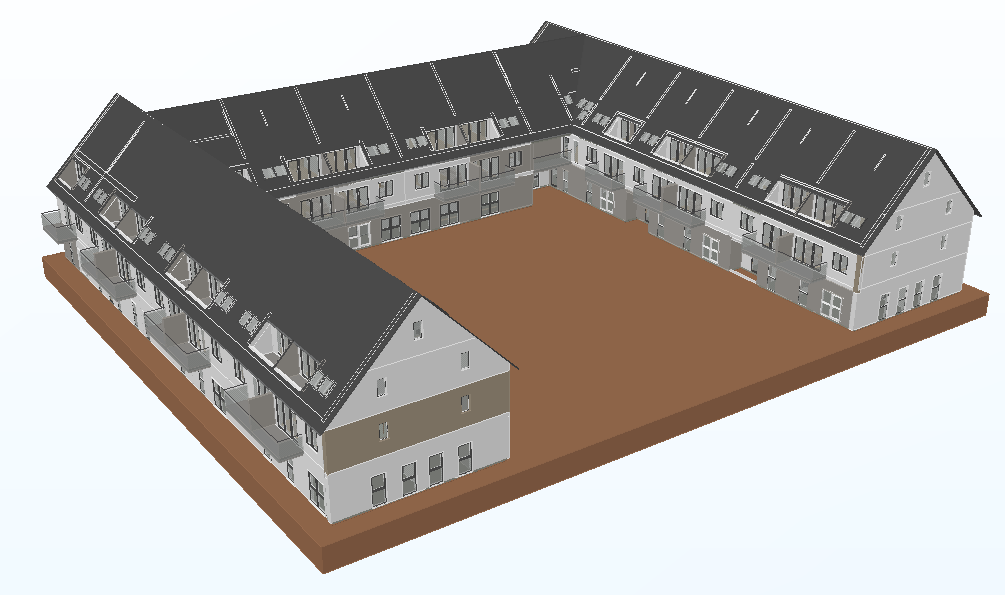

An exciting new development is underway on an area of farmland between Åkarp and Arlöv in Skåne county near Malmö. Named Kronetorp, on completion the project will contain around 7,000 residential and rental apartments, service houses, offices, bathhouses, and schools. Over approximately 15 years, developers in Kronetorp Park AB will provide the feel of a small, suburban town living, with proximity to the big city.

Precast Elements Manufactured On-site

Along with investing in the land, the developers also installed a small precast factory on-site. By manufacturing their own elements, they can control quality and supply for the project. They produced around 14 precast elements per day.

On a visit to the site, we met Johan Birkegård, Factory manager at KP Betong AB. He emphasized the advantages of having a factory on-site; including savings on transport costs, control of delivery schedules, flexibility, and ease of feedback.

In addition to these benefits, there is a positive environmental impact in reducing the project’s carbon footprint.

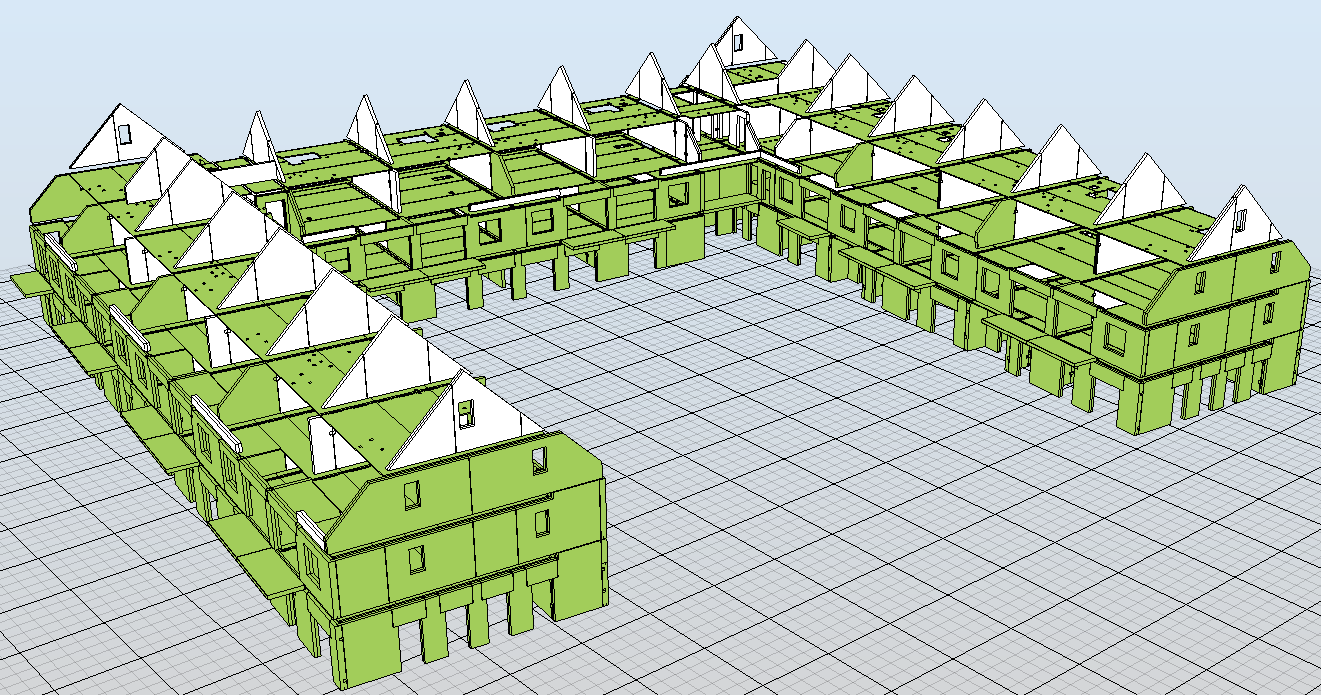

Enabling a 3D BIM (Building Information Modeling) Workflow with StruEngineers

StruEngineers, on behalf of parent company StruSoft, was already involved in four project phases, with a fifth to come.

StruEngineers produced and supplied manufacturing drawings for precast along with reinforcement specifications, machine files, assembly drawings and reports. These drawings were then used in IMPACT for precast elements production and project planning.

The entire schedule worked through a 3D model, allowing complete BIM workflow on cloud. This means accurate control over production planning and eventual transport to the construction site.

“You can see the building in the model and follow along with all the way to plan the casting and assembly arrangement” says Johan.

Every detail is important, such as how precast elements should be loaded to maximize transport efficiency, and how they should be produced to match the transportation times and erection schedule on-site.

“I like IMPACT because it is very user-friendly”

says Johan, having not worked with this type of software before. He received comprehensive training on-site from StruSoft’s Fredrik Arheden, product owner for IMPACT, and managed to solve tasks and become familiar with the work in just a week.

Real-time, Error-free Drawing Support

As production progressed, project revisions and updates were done simultaneously by StruEngineers. If something changed in the drawings, in the database or in the model, it was carried through immediately to the transport and production planning tools.

Therefore, everyone involved followed the process in real-time via a continually updated model and BIM process. Johan confirmed the advantages of this, to planning and efficiency;

“IMPACT helped us to plan our casting tables effectively by using as much of the table surface as possible during each cast. We could always see what was being produced via the model, and this helped us to avoid errors and duplication.”

Johan also showed us a model for a preschool, exporting files out to the factory computer for the production phase. The preschool was completed in November 2019, and was the 4th building constructed using IMPACT, assisted by the precast knowledge of StruEngineers.

We are proud to be a part of this impressive, environmentally focused, and sustainable project, a reality!